Uhlolojikelele lwephrojekthi

1. Uhlelo Lokukhiqiza

600 amasethi/ngosuku (117/118 ehamba ngezinyawo)

2. Izidingo zokucubungula umugqa:

1) isikhungo somshini we-NC esilungele umugqa wokukhiqiza othomathikhi;

2) I-Hydraulic frock clamp;

3) Ukulayisha okuzenzakalelayo kanye nedivaysi yokuvala kanye nedivayisi yokudlulisa;

I-4) Ubuchwepheshe bokucubungula okuphelele kanye nesikhathi somjikelezo wokucubungula;

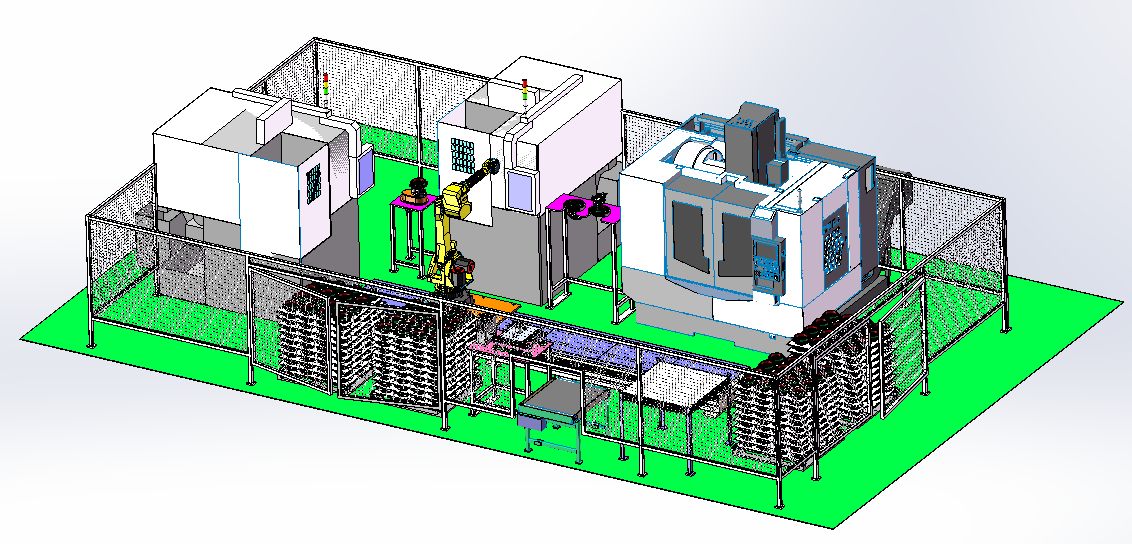

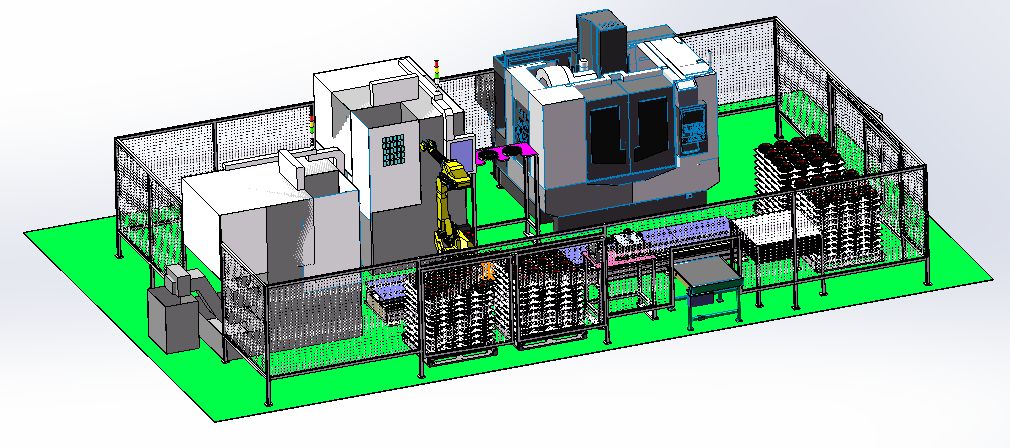

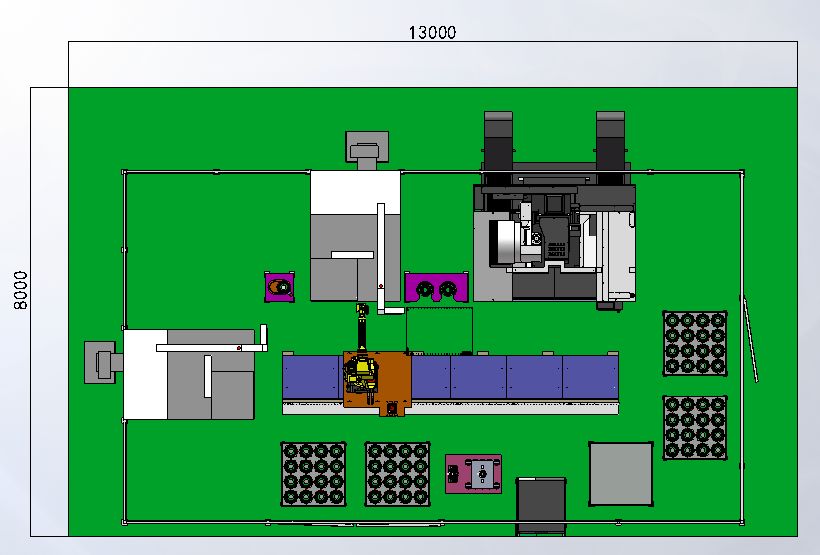

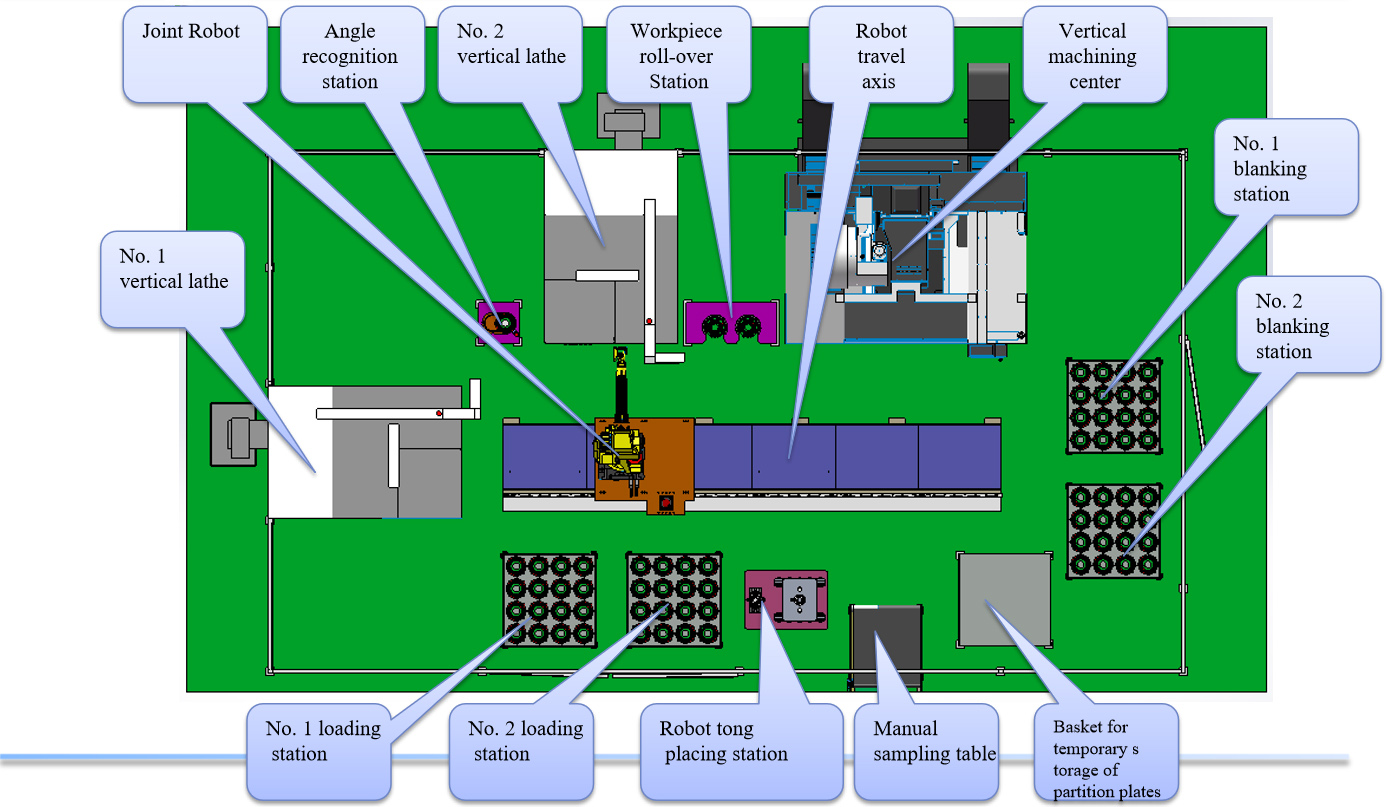

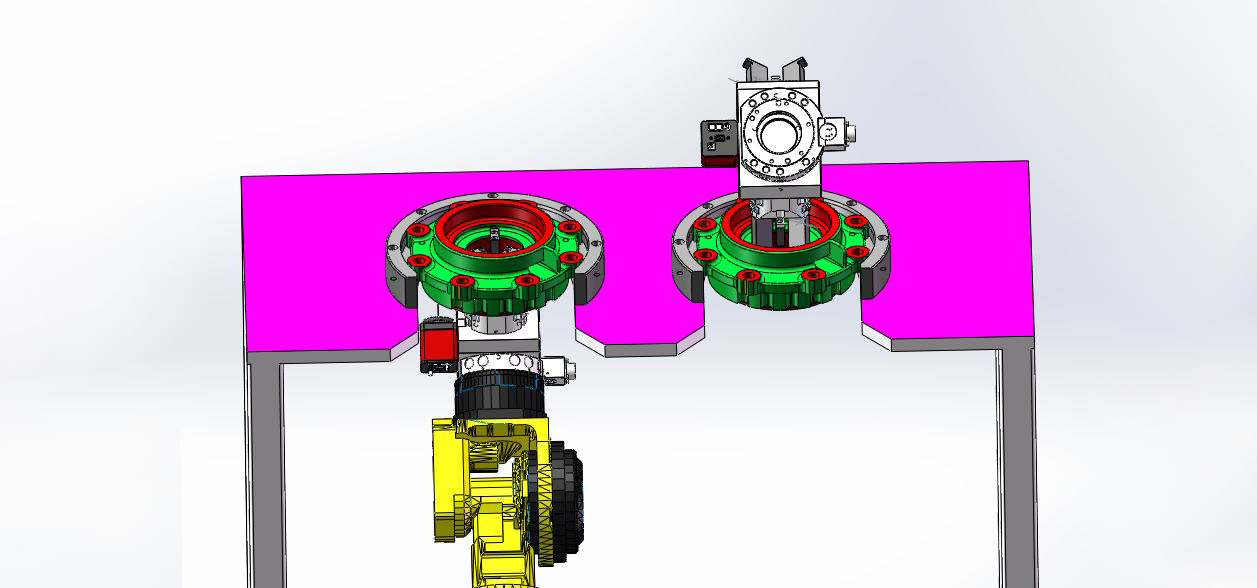

Ukwakheka Kwemigqa Yokukhiqiza

Ukwakheka Kwemigqa Yokukhiqiza

Ukwethulwa Kwezenzo Zerobhothi:

1. Beka mathupha obhasikidi abangomshini nababekwe phezu kwetafula lokulayisha (Ilayisha amathebula No. 1 kanye No. 2) bese ucindezela inkinobho ukuze uqinisekise;

2. Irobhothi liya ethreyini lethebula lokulayisha elingunombolo 1, livula uhlelo lokubona, libambe futhi lihambise Izingxenye A no-B ngokulandelana kwazo ziye esiteshini sokubuka esiyi-angular ukuze silinde umyalelo wokulayisha;

3. Umyalelo wokulayisha uthunyelwa yisiteshi sokuqaphela i-angular. Irobhothi libeka inombolo engu-1 endaweni yokuma ye-turntable. Zungezisa i-turntable bese uqala uhlelo lokuqaphela i-angular, unqume indawo ye-angular, umise i-turntable futhi uqedele ukuqashelwa kwe-angular kwesiqephu esingu-1;

4. Isistimu yokuqaphela i-angular ithumela umyalo ongenalutho, futhi irobhothi lithatha ucezu lwe-No. 1 bese lifaka ucezu lwe-No. 2 ukuze likhonjwe. I-turntable iyazungeza futhi isistimu yokuqaphela angular iqala ukuze inqume indawo ye-angular. I-turntable iyama kanye nokuqashelwa kwe-angular kwesiqephu esingu-2 kuqediwe, futhi umyalo ongenalutho uthunyelwa;

5. Irobhothi lithola umyalo ongenalutho we-lathe eqondile engu-No. 1, liya endaweni yokulayisha kanye nokungasho lutho ye-lathe eqondile engu-No. 1 yokuvala nokulayishwa kwempahla. Ngemva kokuba isenzo sesiqediwe, umjikelezo womshini wocezu olulodwa we-lathe eqondile uyaqala;

6. Irobhothi lithatha imikhiqizo eqediwe ngeNombolo 1 ilele eqondile bese liyibeka endaweni engu-1 kuthebula lokugingqika;

7. Irobhothi lithola umyalo ongenalutho we-lathe eqondile engunombolo 2, liya endaweni yokulayisha nokuvala ye-lathe engunombolo 2 yokuvala nokulayishwa kwempahla., ngemva kwalokho isenzo siyaqedwa, bese kuqala umjikelezo wokucubungula wesiqephu esisodwa se-lathe eqondile;

8. Irobhothi lithatha imikhiqizo eqediwe nge-lathe engu-No. 2 bese liyibeka endaweni engu-2 kuthebula lokugingqika;

9. Irobhothi lilinda umyalo ongasho lutho ovela kumashini aqondile;

10. Imishini eqondile ithumela umyalo ongenalutho, futhi irobhothi liya endaweni yokulayisha nengabhalwa lutho yomshini oqondile, ibambe futhi ihambise izingcezu zokusebenza zeziteshi ze-No. 1 kanye ne-No. Irobhothi liya kuthebula le-roll-over ukuze libambe futhi lithumele izingcezu ze-No. 1 kanye ne-No. 2 endaweni eqondile yokulayisha imishini neyokuvala ngokulandelana, futhi ibeka ucezu lokusebenza onguNombolo 1 noNo. 2 endaweni yokuma engu-No. 1 kanye ne-No. Irobhothi liphuma ebangeni lokuphepha lemishini eqondile futhi liqala umjikelezo wokucubungula owodwa;

11. Irobhothi lithuthela kuthreyi engu-1 yokulayisha futhi lilungiselela ukuqaliswa kohlelo lomjikelezo wesibili;

Incazelo:

1. Irobhothi lithatha izingcezu eziyi-16 (ungqimba olulodwa) kuthreyi yokulayisha. Irobhothi lizongena esikhundleni se-tong yenkomishi yokumunca bese libeka ipuleti lokuhlukanisa kubhasikidi wesikhashana wokugcina;

2. Irobhothi lipakisha izingcezu eziyi-16 (ungqimba olulodwa) ethreyini engenalutho. Irobhothi kufanele lishintshe inkomishi yokumunca kanye, bese libeka ipuleti lokuhlukanisa izingxenye ezisuka kubhasikidi wokugcina wesikhashana;

3. Ngokuvumelana nemvamisa yokuhlola, qiniseka ukuthi irobhothi libeka ingxenye etafuleni lesampula lesampula;

| 1 | Ithebula lezikhathi lomjikelezo womshini | ||||||||||||||

| 2 | Ikhasimende | Impahla yokusebenza | I-QT450-10-GB/T1348 | Imodeli yethuluzi lomshini | Inombolo yomlando | ||||||||||

| 3 | Igama Lomkhiqizo | 117 Ephethe isihlalo | Umdwebo No. | DZ90129320117 | Usuku lokulungiselela | 2020.01.04 | Ilungisiwe ngu | ||||||||

| 4 | Isinyathelo sokucubungula | Ummese No. | okuqukethwe komshini | Igama Lethuluzi | Ukusika Ububanzi | Ukusika isivinini | Isivinini sokujikeleza | Okuphakelayo ngokwenguquko ngayinye | Okuphakelayo ngethuluzi lomshini | Inombolo yokusika | Inqubo ngayinye | Isikhathi somshini | Isikhathi Sokungenzi lutho | Isikhathi sokujikeleza se-axis amane | Isikhathi sokushintsha ithuluzi |

| 5 | Cha. | Cha. | I-Desorptions | Amathuluzi | D mm | n | R pm | mm/Rev | mm/Miniz | Izikhathi | mm | Isiqephu | Isiqephu | Isiqephu | |

| 6 |  | ||||||||||||||

| 7 | 1 | T01 | Milling hole surface | Ububanzi be-milling cutter enobuso obungu-40 | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | |

| 8 | Bamba izimbobo ezifakwayo ezingu-DIA eziyi-17 | I-DIA 17 I-DRILL Ehlanganisiwe | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||

| 9 | T03 | DIA 17 hole back chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | ||

| 10 | Incazelo: | Isikhathi sokusika: | 62 | Okwesibili | Isikhathi sokubopha nge-fixture kanye nokulayisha nokuvala izinto: | 30.00 | Okwesibili | ||||||||

| 11 | Isikhathi sokusiza: | 44 | Okwesibili | Isamba samahora omuntu wokwenza imishini: | 136.27 | Okwesibili | |||||||||

| 1 | Ithebula lezikhathi lomjikelezo womshini | |||||||||||||||||

| 2 | Ikhasimende | Impahla yokusebenza | I-QT450-10-GB/T1348 | Imodeli yethuluzi lomshini | Inombolo yomlando | |||||||||||||

| 3 | Igama Lomkhiqizo | 118 Ephethe isihlalo | Umdwebo No. | DZ90129320118 | Usuku lokulungiselela | 2020.01.04 | Ilungisiwe ngu | |||||||||||

| 4 | Isinyathelo sokucubungula | Ummese No. | okuqukethwe komshini | Igama Lethuluzi | Ukusika Ububanzi | Ukusika isivinini | Isivinini sokujikeleza | Okuphakelayo ngokwenguquko ngayinye | ukudla ngethuluzi lomshini | Inombolo yokusika | Inqubo ngayinye | Isikhathi somshini | Isikhathi Sokungenzi lutho | Isikhathi sokujikeleza se-axis amane | Isikhathi sokushintsha ithuluzi | |||

| 5 | Cha. | Cha. | I-Desorptions | Amathuluzi | D mm | n | R pm | mm/Rev | mm/Miniz | Izikhathi | mm | Isiqephu | Isiqephu | Isiqephu | ||||

| 6 |

| |||||||||||||||||

| 7 | 1 | T01 | Milling hole surface | Ububanzi be-milling cutter enobuso obungu-40 | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | ||||

| 8 | T02 | Bamba izimbobo ezifakwayo ezingu-DIA eziyi-17 | I-DIA 17 I-DRILL Ehlanganisiwe | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||||

| 9 | T03 | DIA 17 hole back chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | |||||

| 10 | Incazelo: | Isikhathi sokusika: | 62 | Okwesibili | Isikhathi sokubopha nge-fixture kanye nokulayisha nokuvala izinto: | 30.00 | Okwesibili | |||||||||||

| 11 | Isikhathi sokusiza: | 44 | Okwesibili | Isamba samahora omuntu wokwenza imishini: | 136.27 | Okwesibili | ||||||||||||

| 12 | ||||||||||||||||||

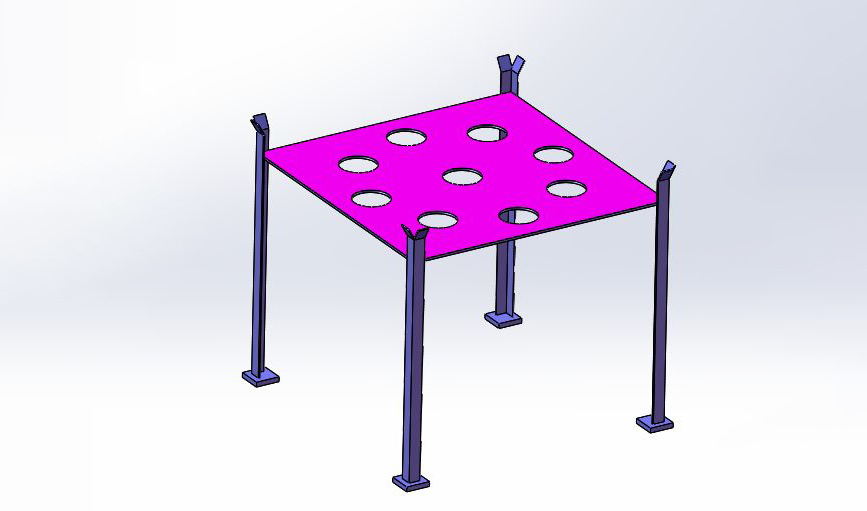

Indawo ehlanganisa umugqa wokukhiqiza

Ukwethulwa kwezingxenye eziyinhloko zokusebenza komugqa wokukhiqiza

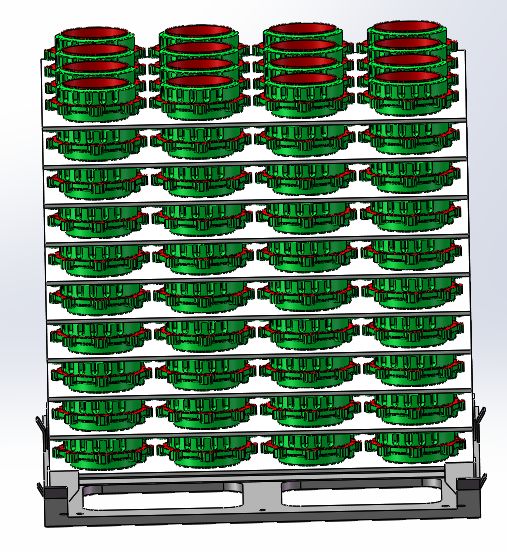

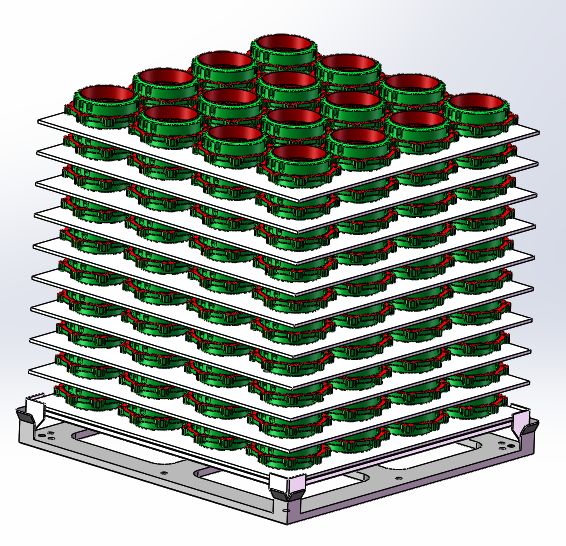

Ukwethulwa kohlelo lokulayisha nokuvala

Impahla yokugcina yolayini wokukhiqiza othomathikhi kulolu hlelo yilena: Ithreyi estakiwe (inani lezingcezu ezizopakishwa kuthreyi ngayinye kuzoxoxiswana ngayo nekhasimende), futhi ukuma kwendawo yokusebenza ethreyini kuzonqunywa ngemva kokunikeza umdwebo we-3D wesiqephu sokusebenza esingenalutho noma into yangempela.

1. Abasebenzi bapakisha izingxenye ezicutshunguliwe ethreyini yezinto ezibonakalayo (njengoba kukhonjisiwe esithombeni) futhi baziphakamisele endaweni ebekiwe;

2. Ngemva kokufaka esikhundleni sethreyi ye-forklift, cindezela ngesandla inkinobho ukuze uqinisekise;

3. Irobhothi libamba ucezu lokusebenza ukwenza umsebenzi wokulayisha;

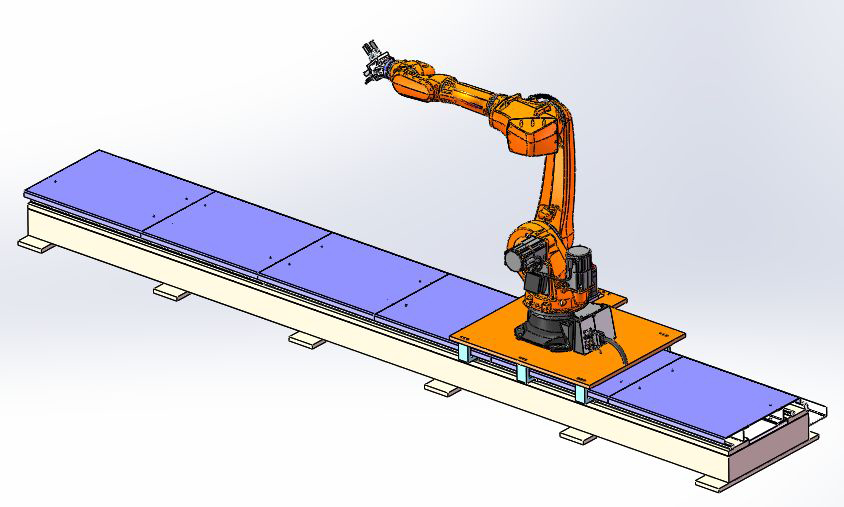

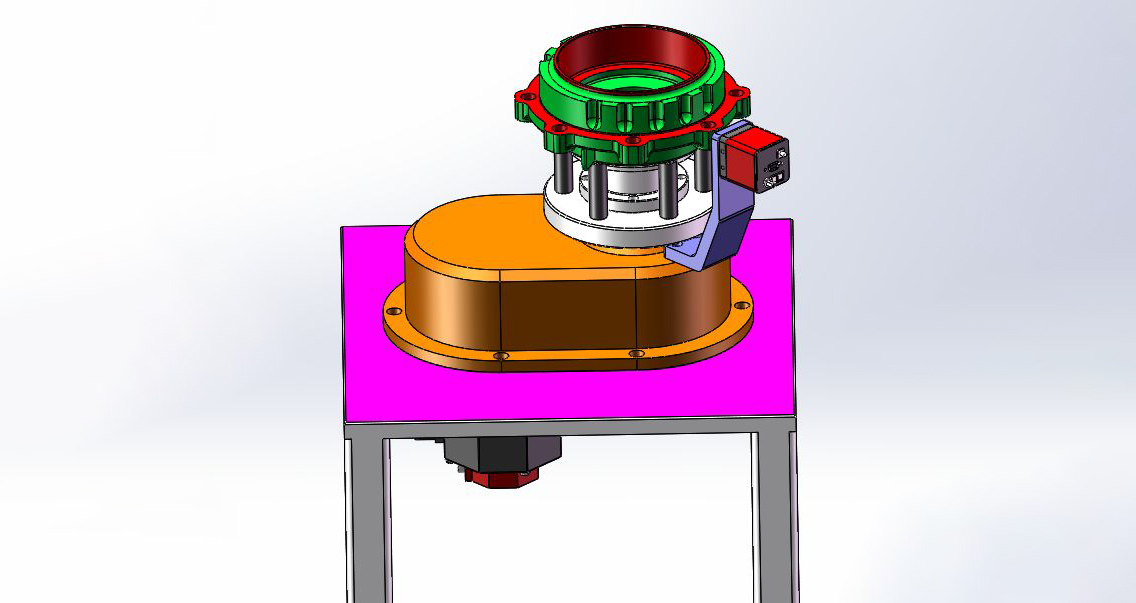

Ukwethulwa kwe-Robot Travel Axis

Isakhiwo sakhiwe irobhothi elihlanganyelwe, i-servo motor drive kanye ne-pinion ne-rack drive, ukuze irobhothi likwazi ukwenza ukunyakaza kwe-rectilinear emuva naphambili. Ibona umsebenzi werobhothi elilodwa elinikeza amathuluzi emishini eminingi kanye nezinto zokusebenza ezibambayo eziteshini eziningana futhi lingandisa ukumbozwa kokusebenza kwamarobhothi ahlangene;

Ithrekhi yokuhamba isebenzisa isisekelo esishiselwe ngamapayipi ensimbi futhi ishayelwa yi-servo motor, pinion kanye ne-rack drive, ukwandisa ukumboza ukusebenza kwerobhothi elihlanganyelwe futhi kuthuthukiswe ngempumelelo izinga lokusetshenziswa kwerobhothi; Ithrekhi yokuhamba ifakwe phansi;

Irobhothi le-Chenxuan:SDCX-RB500

| Idatha eyisisekelo | |

| Uhlobo | I-SDCX-RB500 |

| Inombolo yezimbazo | 6 |

| Ukufakwa okuphezulu | 2101mm |

| Ukuphindaphinda kokuma (ISO 9283) | ±0.05mm |

| Isisindo | 553kg |

| Isigaba sokuvikela irobhothi | Isilinganiso sokuvikela, IP65 / IP67isihlakala esisemgqeni(IEC 60529) |

| Indawo yokukhweza | Uphahla, i-engeli evumelekile yokuthambekela ≤ 0º |

| Ukuphela kwendawo, umsebenzi wokupenda | Uhlaka oluyisisekelo: olumnyama (RAL 9005) |

| Izinga lokushisa le-ambient | |

| Ukusebenza | 283 K kuya ku-328 K (0 °C kuya +55 °C) |

| Isitoreji kanye nezinto zokuhamba | 233 K kuya ku-333 K (-40 °C kuya +60 °C) |

Ngesizinda esibanzi esinyakazayo ngemuva nangaphansi kwerobhothi, okuyimodeli ekwazi ukugxunyekwa ngokuphakanyiswa kosilingi. Ngenxa yokuthi ububanzi bezinhlangothi zerobhothi buncishisiwe baze bafika emkhawulweni, kungenzeka ukufakwa eduze nerobhothi eliseduze, i-clamp, noma ucezu lokusebenza. Ukunyakaza kwesivinini esikhulu ukusuka endaweni elindile kuya endaweni yokusebenza kanye nokuma ngokushesha phakathi nokunyakaza kwebanga elifushane.

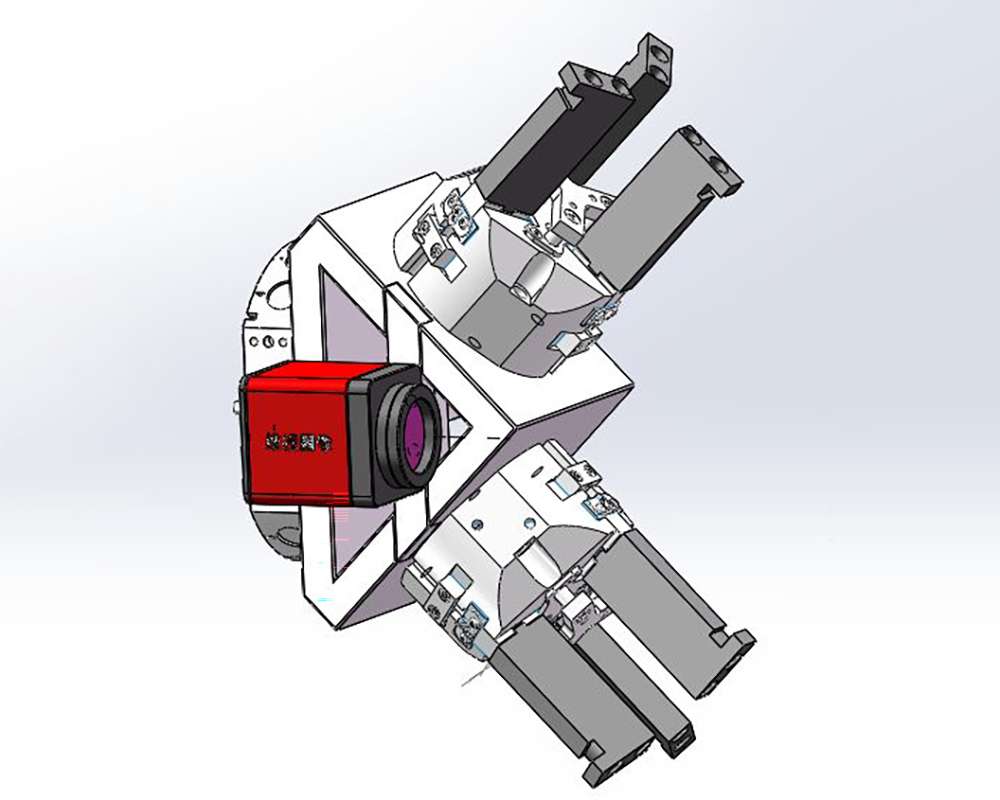

Irobhothi elihlakaniphile lokulayisha kanye nendlela ye-blanking tong

I-Robot partition plate tong mechanism

Incazelo:

1. Uma sicabangela izici zale ngxenye, sisebenzisa indlela esekela yangaphandle enezinzipho ezintathu ukuze silayishe futhi sivale izinto ezisetshenziswayo, ezikwazi ukubona ukuphenduka ngokushesha kwezingxenye zethuluzi lomshini;

2. Umshini ufakwe inzwa yokubona indawo kanye nenzwa yokucindezela ukuze ibone ukuthi isimo sokugoqa kanye nokucindezela kwezingxenye kujwayelekile;

3. Umshini ufakwe i-pressurizer, futhi i-workpiece ngeke siwe ngesikhathi esifushane uma kwenzeka ukwehluleka kwamandla kanye nokunqanyulwa kwegesi kumjikelezo womoya omkhulu;

4. Idivayisi yokushintsha isandla iyamukelwa. Ukushintsha indlela ye-tong kungaqeda ngokushesha ukubopha kwezinto ezihlukahlukene.

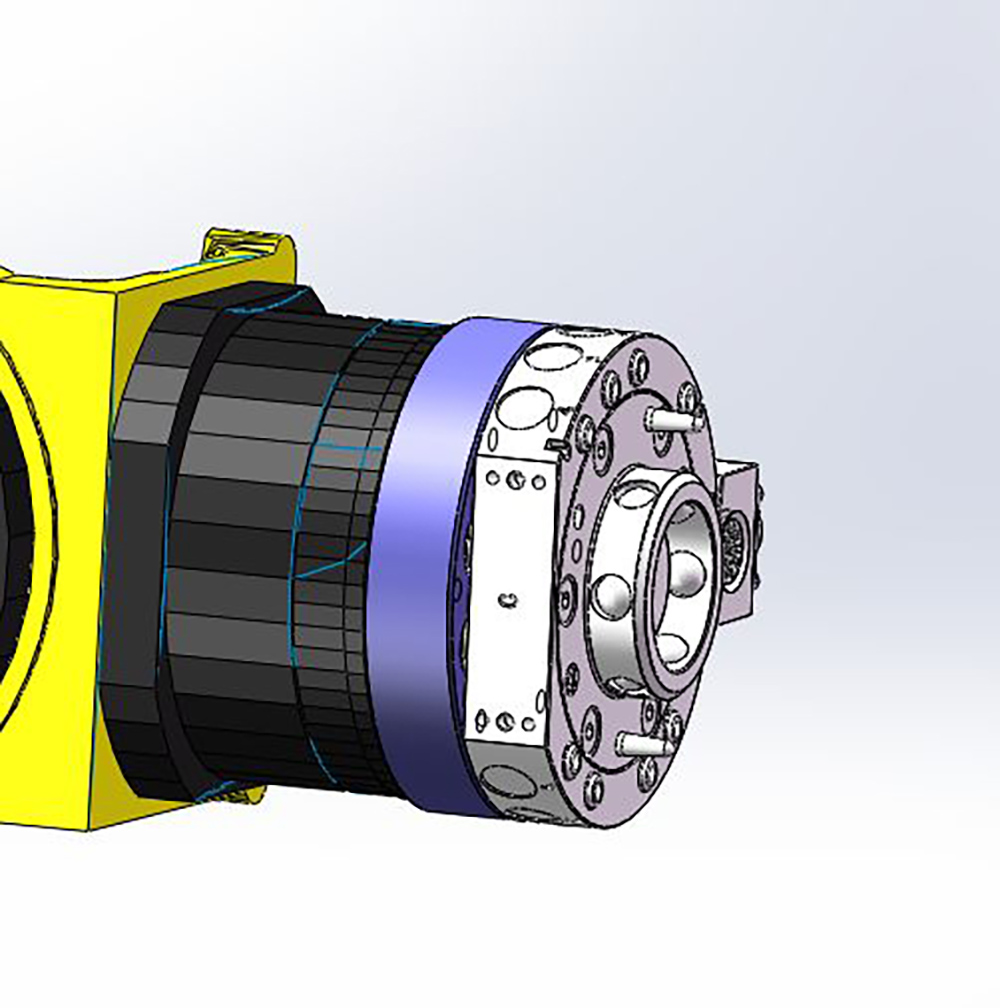

Ukwethulwa kwe-Tong Changing Device

Idivayisi enembile yokushintsha ithoni isetshenziselwa ukushintsha ngokushesha izidlawu zamarobhothi, iziphetho zamathuluzi, nezinye izisetshenziswa. Yehlisa isikhathi sokungenzi lutho sokukhiqiza futhi ukhuphule ukuguquguquka kwerobhothi, okufakwe njengokuthi:

1. Vula futhi uqinise umfutho womoya;

2. Amamojula ahlukahlukene wamandla, uketshezi kanye negesi angasetshenziswa;

3. Ukucushwa okujwayelekile kungaxhuma ngokushesha nomthombo womoya;

4. Izikhungo zomshwalense ezikhethekile zingavimbela ingozi yokunqanyulwa kwegesi ngengozi;

5. Awekho amandla okusabela entwasahlobo; 6. Isebenza emkhakheni we-automation;

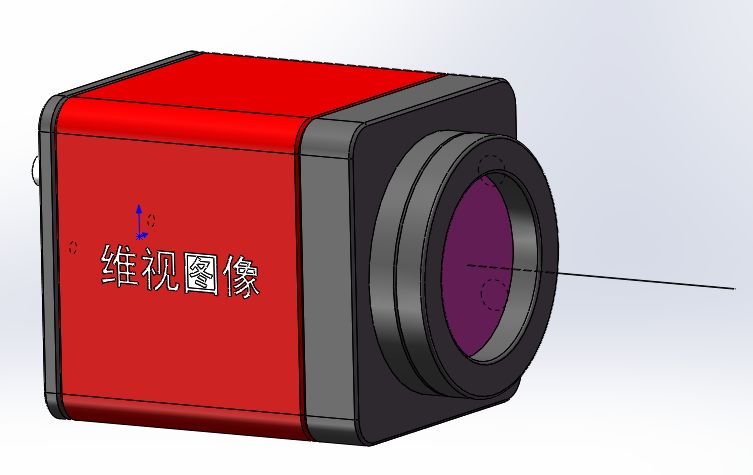

Isingeniso se-Vision System-Industrial Camera

1. Ikhamera yamukela ama-chips e-CCD kanye ne-CMDS ekhwalithi ephezulu, anezici zesilinganiso sokuxazulula okuphezulu, ukuzwela okuphezulu, isilinganiso esiphezulu sesignali-to-frequency, ububanzi obuguquguqukayo, ikhwalithi yesithombe esihle kakhulu kanye nekhono lokubuyisela umbala wesigaba sokuqala;

2. Ikhamera yendawo yekhamera inezinhlobo ezimbili zokudlulisa idatha: isikhombimsebenzisi se-GIGabit Ethernet (GigE) nesixhumi esibonakalayo se-USB3.0;

3. Ikhamera inokwakheka okuhlangene, ukubukeka okuncane, engasindi futhi ifakiwe. Ijubane eliphezulu lokudlulisa, ikhono eliqinile lokulwa nokuphazamiseka, ukuphuma okuzinzile kwesithombe sekhwalithi ephezulu; Isebenza ekufundeni amakhodi, ukutholwa kokukhubazeka, i-DCR nokubonwa kwephethini; Ikhamera yombala inekhono eliqinile lokubuyisela umbala, ifanele izimo ezinemfuneko ephezulu yokuqaphela umbala;

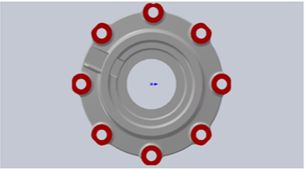

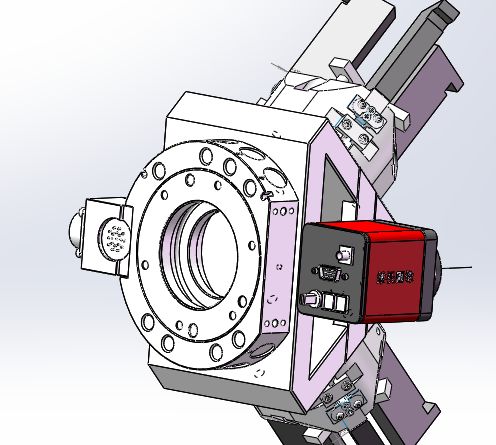

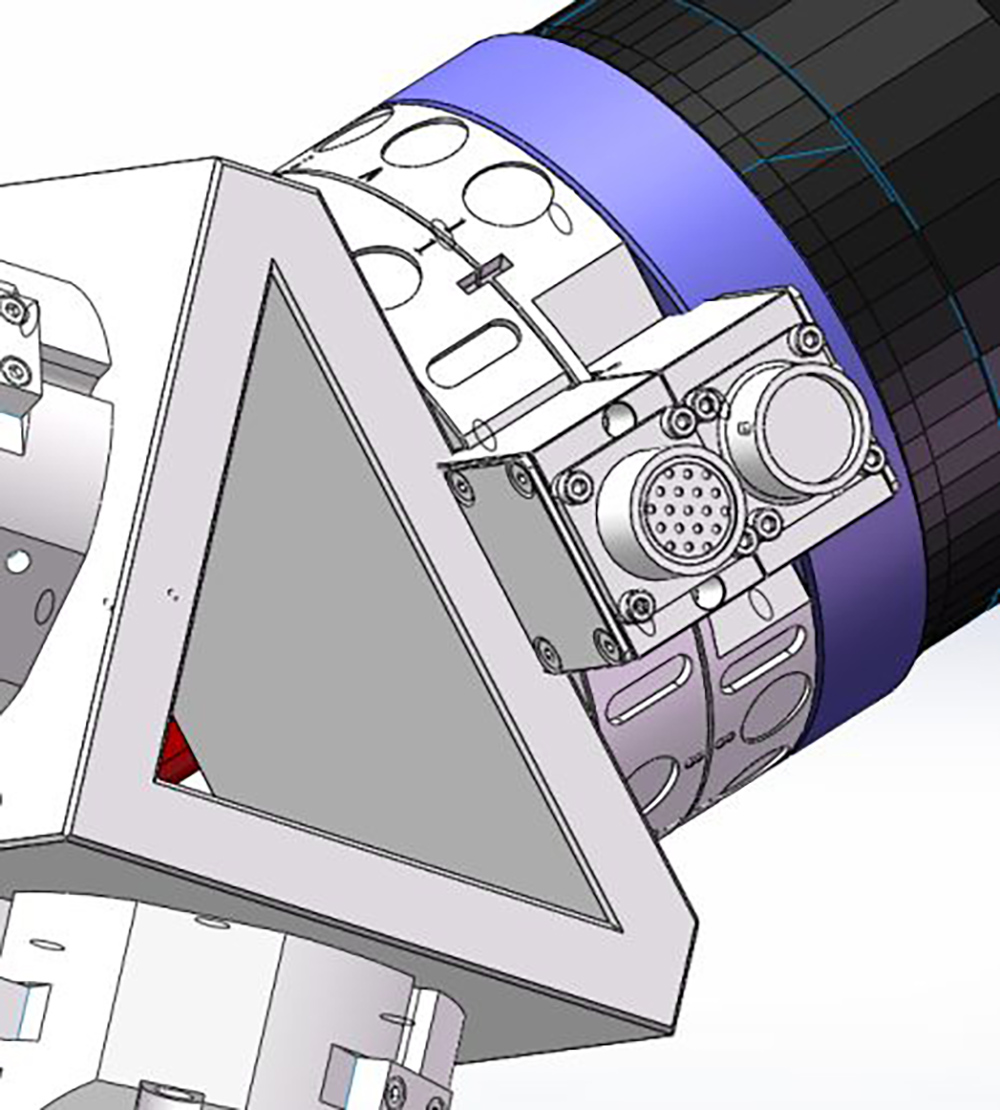

Ukwethulwa kwe-Angular Automatic Recognition System

Isingeniso Somsebenzi

1. Irobhothi liqinisa ama-workpieces kusuka kubhasikidi abalayishayo futhi lizithumela endaweni yokuma ye-turntable;

2. I-Turntable izungeza ngaphansi kokushayela kwe-servo motor;

3. Isistimu yokubuka (ikhamera yezimboni) isebenza ukukhomba indawo ye-angular, futhi i-turntable iyama ukuze inqume indawo edingekayo ye-angular;

4. Irobhothi likhipha ucezu lokusebenza bese lifaka olunye ucezu ukuze lihlonzwe i-angular;

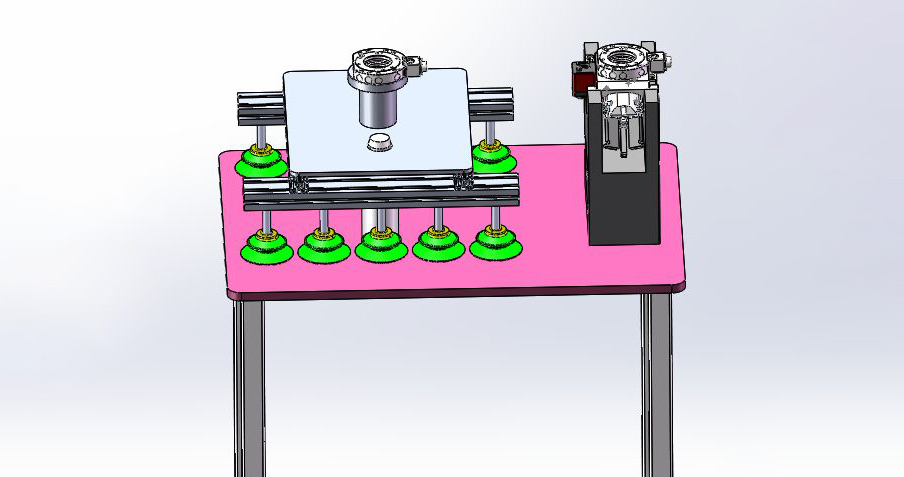

Isingeniso Sethebula le-Workpiece Roll-over

Isiteshi esiphumayo:

1. Irobhothi lithatha ucezu lomsebenzi liwubeke endaweni yokubeka phezu kwetafula eligoqayo (isiteshi esingakwesokunxele emfanekisweni);

2. Irobhothi libamba ucezu lokusebenza kusuka kokungenhla ukuze libone ukugingqika komsebenzisi;

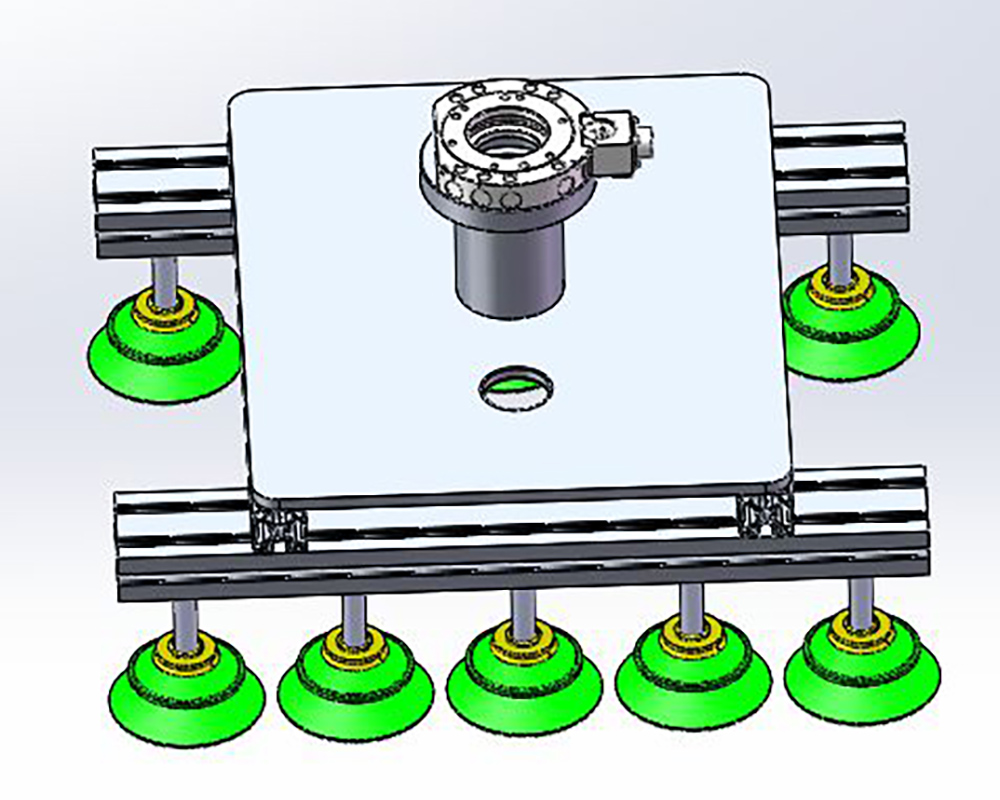

Itafula lokubeka i-robot tong

Isingeniso Somsebenzi

1. Ngemuva kokuthi ungqimba ngalunye lwezingxenye lulayishiwe, ipuleti lokuhlukanisa elendlalekile lizofakwa kubhasikidi wesikhashana wokugcina amapuleti okuhlukanisa;

2. Irobhothi lingashintshwa ngokushesha ngodlawu lwenkomishi yokumunca ngesisetshenziswa esishintshayo bese sikhipha amapuleti ahlukanisayo;

3. Ngemva kokuba amapuleti okuhlukanisa esebekwe kahle, khumula itong yenkomishi yokumunca bese ufaka ithongo lomoya ukuze uqhubeke nokulayisha nokuvala izinto;

Ubhasikidi wokugcinwa kwesikhashana kwamapuleti okuhlukanisa

Isingeniso Somsebenzi

1. Ubhasikidi wesikhashana wamapuleti okuhlukanisa uyaklanywa futhi uhlelwe njengoba amapuleti okuhlukanisa ukuze alayishwe ehoxiswa kuqala futhi amapuleti okuhlukanisa asetshenziswe kamuva;

2. Amapuleti okuhlukanisa okulayisha abekwe ngesandla futhi awahambisani kahle. Ngemuva kokuthi ipuleti lokuhlukanisa lifakwe kubhasikidi wokugcina wesikhashana, irobhothi lingakwazi ukulikhipha futhi lilibeke kahle;

Ithebula lesampula lenziwa ngesandla

Incazelo:

1. Setha imvamisa yesampula engahleliwe yemanuwali ehlukene yezigaba zokukhiqiza ezihlukene, ezingagada ngempumelelo ukuphumelela kokulinganisa ku-inthanethi;

2. Imiyalelo Yokusetshenziswa: I-manipulator izobeka ucezu lokusebenza endaweni emisiwe etafuleni lesampula ngokuya ngefrikhwensi esethwe ngesandla, futhi isheshe ikhanyise ngesibani esibomvu. Umhloli uzocindezela inkinobho yokuhambisa i-workpiece endaweni yokuphepha ngaphandle kwesivikelo, akhiphe ucezu lomsebenzi ukuze alwelwe futhi alugcine ngokuhlukile ngemva kokulinganisa;

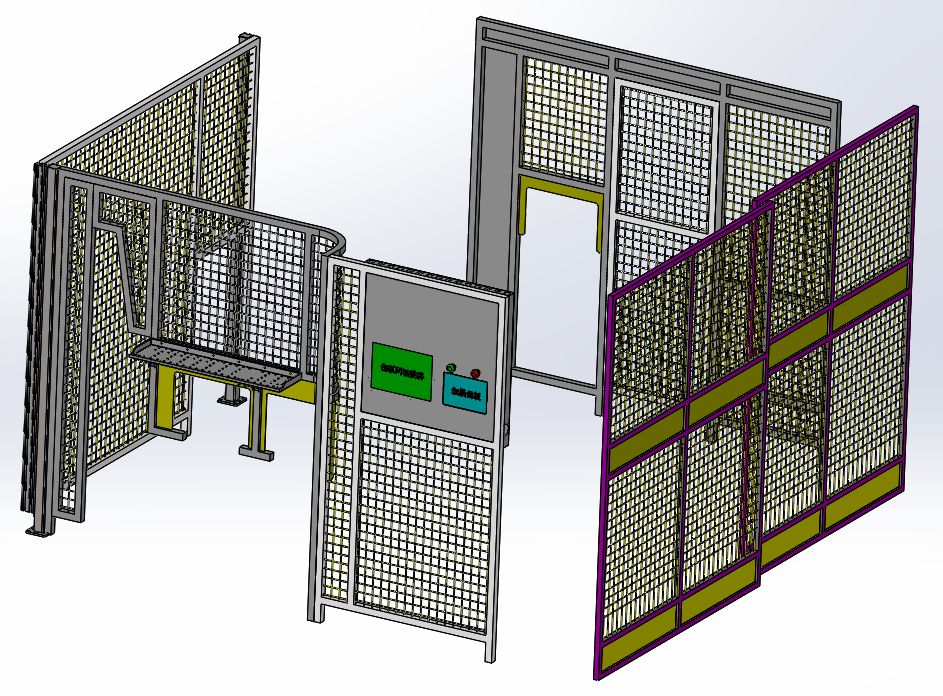

Izingxenye zokuzivikela

Yakhiwe ngephrofayela ye-aluminium engasindi (40×40)+mesh (50×50), futhi isikrini sokuthinta kanye nenkinobho yokumisa izimo eziphuthumayo ingahlanganiswa nezingxenye zokuzivikela, ihlanganise ukuphepha nobuhle.

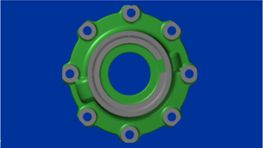

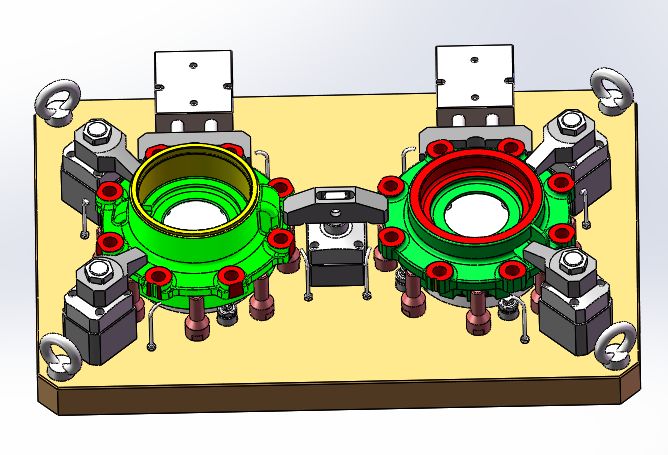

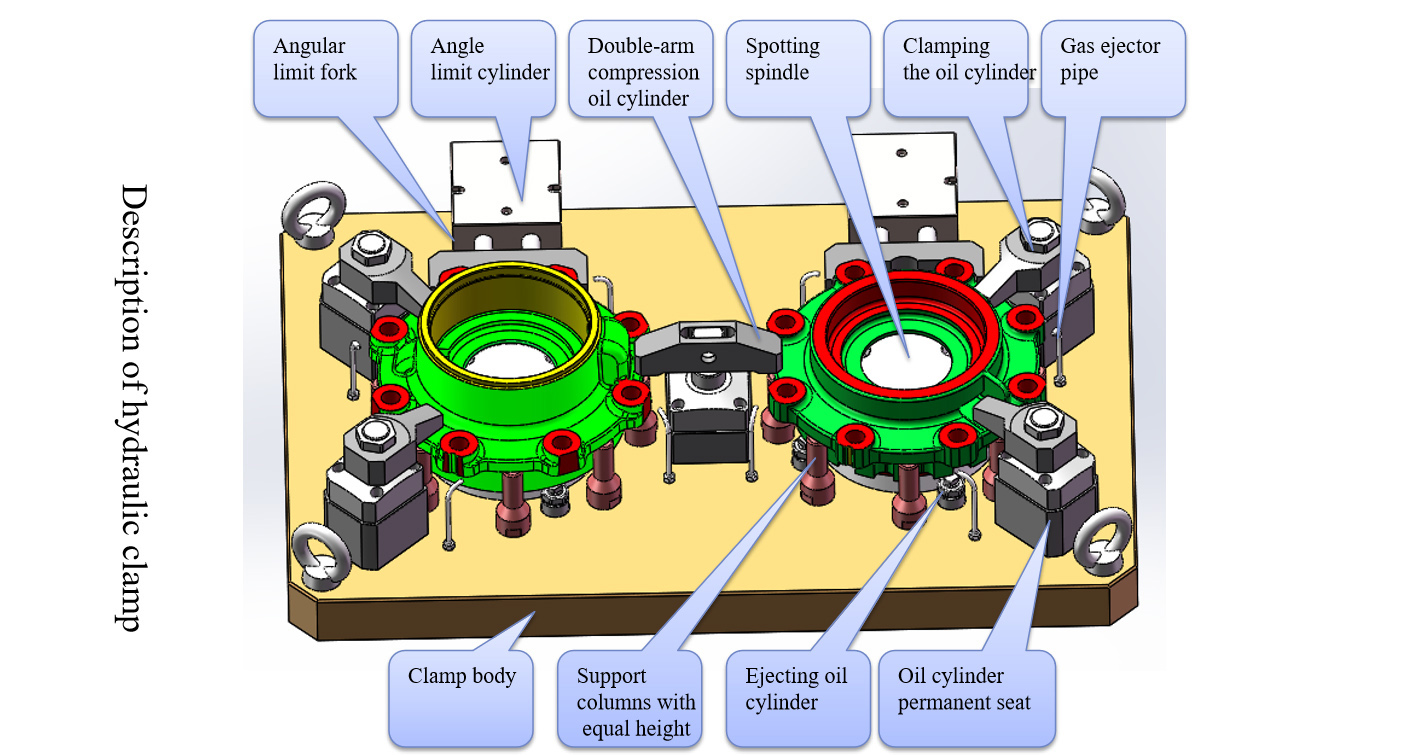

Ukwethulwa kwe-OP20 Hydraulic Fixture

Imiyalo Yokucubungula:

1. Thatha u-φ165 ongaphakathi njengembobo yesisekelo, thatha i-D datum njengendiza eyisisekelo, bese uthatha i-arc yangaphandle yomphathi wezimbobo ezimbili ezifakwayo njengomkhawulo we-angular;

2. Lawula ukuxegiswa nokucindezela kwesenzo sepuleti lokucindezela ngomyalo wethuluzi lomshini M ukuze uqedele ukucubungula kwe-chamfering yendiza engaphezulu yomphathi wembobo ekhuphukayo, imbobo engu-8-φ17 kanye neziphetho zombili zembobo;

3. Isakhiwo sinomsebenzi wokumisa indawo, ukugoqa okuzenzakalelayo, ukubona ukucinana komoya, ukuzikhulula okuzenzakalelayo, ukukhishwa okuzenzakalelayo, ukushaywa kwe-chip okuzenzakalelayo kanye nokuhlanza okuzenzakalelayo kwendiza yedatha;

Izidingo Zezisetshenziswa Zolayini Wokukhiqiza

1. I-clamp yomshini wokukhiqiza inemisebenzi yokuphoqa okuzenzakalelayo kanye nokukhulula, futhi ibona imisebenzi yokuphoqa nokukhulula okuzenzakalelayo ngaphansi kokulawulwa kwamasignali wesistimu ye-manipulator ukuze ibambisane nesenzo sokulayisha nokuvala;

2. Isikhundla se-skylight noma imojula yomnyango othomathikhi izogcinelwa ipuleti lensimbi lemishini yomugqa wokukhiqiza, ukuze ihambisane nesiginali yokulawula kagesi kanye nokuxhumana kwe-manipulator yenkampani yethu;

3. Imishini yokukhiqiza inokuxhumana ne-manipulator ngokusebenzisa imodi yokuxhuma yesixhumi esithwala kanzima (noma ipulaki yendiza);

4. Imishini yokukhiqiza inesikhala sangaphakathi (sokuphazamisa) esikhulu kunohlu oluphephile lwesenzo somhlathi we-manipulator;

5. Impahla kalayini wokukhiqiza kufanele iqinisekise ukuthi awekho amashidi ensimbi ayinsalela endaweni yokuma ye-clamp. Uma kunesidingo, ukuvunguza komoya kuzokwenyuswa ukuze kuhlanzwe (i-chuck izojikeleza lapho ihlanzwa);

6. Imishini yokukhiqiza ine-chip enhle yokuphuka. Uma kunesidingo, isisetshenziswa esisizayo sokuphula i-chip yenkampani yethu siyokwengezwa;

7. Lapho umshini wokukhiqiza umshini udinga ukuma okunembile kwe-spindle yethuluzi lomshini, engeza lo msebenzi futhi unikeze amasignali ahambisanayo kagesi;

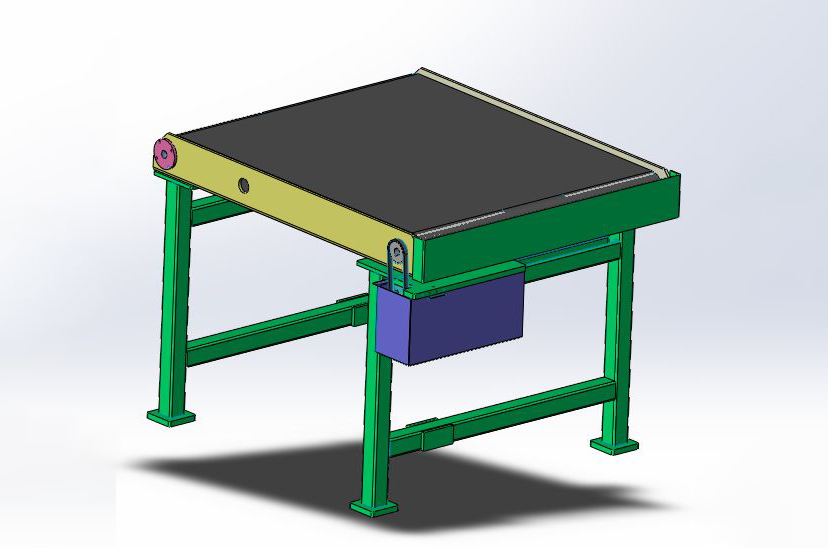

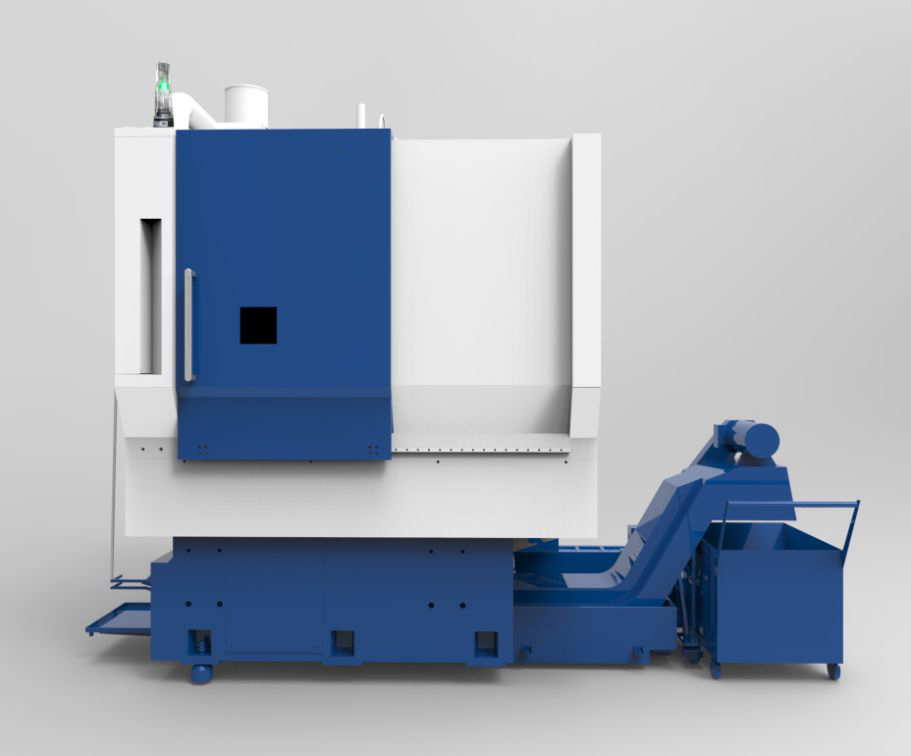

Ukwethulwa kwe-Vertical Lathe VTC-W9035

I-VTC-W9035 NC lathe eqondile ilungele ukukhanda izingxenye ezijikelezayo ezifana nezikhala zegiya, ama-flange namagobolondo anomumo okhethekile, afaneleka ngokukhethekile ukushintshwa kwezingxenye ezifana namadiski, amahabhu, ama-brake discs, imizimba yephampu, imizimba yama-valve namagobolondo. Ithuluzi lomshini linezinzuzo zokuqina okuhle okuphelele, ukunemba okuphezulu, izinga elikhulu lokususwa kwensimbi ngesikhathi seyunithi, ukugcinwa kokunemba okuhle, ukwethembeka okuphezulu, ukugcinwa okulula, njll kanye nobubanzi bezinhlelo zokusebenza. Ukukhiqizwa komugqa, ukusebenza kahle okuphezulu kanye nezindleko eziphansi.

| Uhlobo lwemodeli | I-VTC-W9035 |

| Ubukhulu bokuphenduka ububanzi bomzimba wombhede | Φ900 mm |

| Ubukhulu bokujika ububanzi kupuleti elishelelayo | Φ590 mm |

| Ubukhulu bokujika ububanzi be-workpiece | Φ850 mm |

| Ubude obukhulu bokujika be-workpiece | 700 mm |

| Ibanga lejubane le-spindle | 20-900 r/min |

| Uhlelo | I-FANUC 0i - TF |

| I-stroke enkulu ye-eksisi ye-X/Z | 600/800 mm |

| Isivinini esisheshayo se-X/Z eksisi | 20/20 m/min |

| Ubude, ububanzi nobude bethuluzi lomshini | 3550*2200*3950 mm |

| Amaphrojekthi | Iyunithi | Ipharamitha | |

| Icubungula ububanzi | Uhambo lwe-X eksisi | mm | 1100 |

| Uhambo lwe-X eksisi | mm | 610 | |

| Uhambo lwe-X eksisi | mm | 610 | |

| Ibanga ukusuka ekhaleni lokuphotha ukuya endaweni yokusebenza | mm | 150-760 | |

| Ibhentshi lokusebenzela | Usayizi webhentshi lokusebenzela | mm | 1200×600 |

| Umthamo omkhulu webhentshi lokusebenzela | kg | 1000 | |

| I-T-groove (usayizi×ubuningi×isikhala) | mm | 18×5×100 | |

| Ukondla | Isivinini sokuphakela esisheshayo se-eksisi ye-X/Y/Z | m/min | 36/36/24 |

| I-spindle | Imodi yokushayela | Uhlobo lwebhande | |

| I-spindle taper | I-BT40 | ||

| Isivinini esikhulu sokusebenza | r/min | 8000 | |

| Amandla (Kaliwe/Ubukhulu) | KW | 11/18.5 | |

| I-Torque (Ikaliwe/Ephezulu) | N·m | 52.5/118 | |

| Ukunemba | X/Y/Z ukunemba kokuma kwe-eksisi (iluphu evalwe uhhafu) | mm | 0.008 (ubude obuphelele) |

| Ukunemba kokuphinda kwe-eksisi ye-X/Y/Z (iluphu evalwe uhhafu) | mm | 0.005 (ubude obuphelele) | |

| Umagazini wamathuluzi | Uhlobo | Idiski | |

| Amandla omagazini wethuluzi | 24 | ||

| Ubukhulu bosayizi wethuluzi(Ububanzi bethuluzi eligcwele/akunalutho ithuluzi eliseduze ububanzi/ubude) | mm | Φ78/Φ150/ 300 | |

| Isisindo sethuluzi esiphezulu | kg | 8 | |

| Okunhlobonhlobo | Umfutho wokunikezwa komoya | I-MPa | 0.65 |

| Umthamo wamandla | I-KVA | 25 | |

| Ubukhulu obuphelele bethuluzi lomshini (ubude×ububanzi×ubude) | mm | 2900×2800×3200 | |

| Isisindo sethuluzi lomshini | kg | 7000 | |