Ukuhlaziywa Kwenqubo Yomugqa Wokukhiqiza

I-Die retrorei im technischen prozess

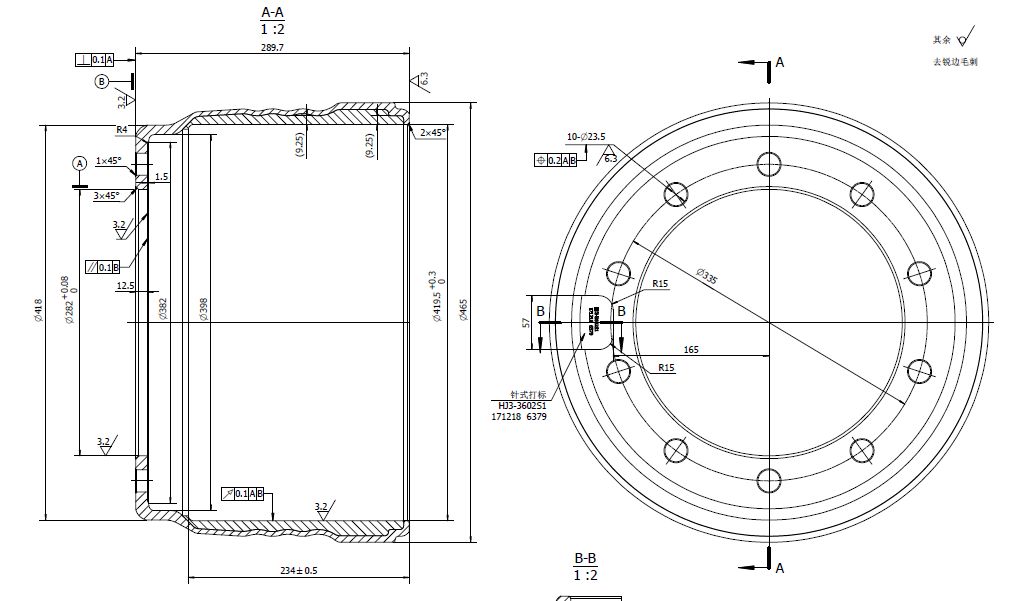

1. Inqubo yokubopha okulahlwayo iyamukelwa ngesikhathi sokujika. Ukuguqula zonke izingxenye zemishini, kufaka phakathi indawo engezansi yezinto zokusebenza.

2. Ngesikhathi sokumba, ama-clamp asebenza ngogesi kufanele asetshenziselwe ukuthola ububanzi obungaphakathi obungu-Φ282 kanye nobuso obungaphezulu, ukubhoboza imbobo engu-10-Φ23.5 kanye ne-chamfering nhlangothi zombili, bese kugaywa indawo yokumaka ye-pneumatic;

Uhlu Lwezisetshenziswa

| OP10 machining Cycle timer | |||||||||||||||

| Incazelo yomzila |

| ||||||||||||||

| Ikhasimende | Impahla yokusebenza | 45 | Imodeli yethuluzi lomshini | Inombolo yomlando | |||||||||||

| Igama Lomkhiqizo | Ukusika ithuluzi shaft izingxenye ezishiselwe | Umdwebo No. | Usuku lokulungiselela | 2021.1.19 | Ilungisiwe ngu | ||||||||||

| Isinyathelo sokucubungula | Ummese No. | okuqukethwe komshini | Igama Lethuluzi | Ukusika Ububanzi | Ukusika isivinini | Isivinini sokujikeleza | Okuphakelayo ngokwenguquko ngayinye | ukudla ngethuluzi lomshini | Inombolo yokusika | Inqubo ngayinye | Isikhathi somshini | Isikhathi Sokungenzi lutho | Qinisa futhi uxege | Isikhathi sokushintsha ithuluzi | |

| Cha. | Cha. | I-Desorptions | Amathuluzi | D mm | VcM/min | R pm | mm/Rev | mm/Miniz | Izikhathi | Ubude mm | Isiqephu | Isiqephu | Isiqephu | ||

| 1 | T01 | Gcoba kancane ubuso obungaphezulu | 455.00 | 450 | 315 | 0.35 | 110 | 1 | 20.0 | 10.89 | 3 | 3 | |||

| 2 | T02 | Lathe cishe i-DIA 419.5 inner bore, i-DIA 382 step face kanye ne-DIA 282 yangaphakathi bore | 419.00 | 450 | 342 | 0.35 | 120 | 1 | 300.0 | 150.36 | 3 | 3 | |||

| 3 | T03 | Gcoba kahle ubuso bokuphela | 455.00 | 450 | 315 | 0.25 | 79 | 1 | 20.0 | 15.24 | 3 | ||||

| 4 | T04 | Lathe ngokunembile i-DIA 419.5 yangaphakathi bore, DIA 382 step face kanye ne-DIA 282 yangaphakathi bore | 369.00 | 450 | 388 | 0.25 | 97 | 1 | 300. 0 | 185.39 | |||||

| 5 | T05 | Layiza ngokuhlehlayo futhi cishe ubuso obuphansi bomkhawulo | 390.00 | 420 | 343 | 0.35 | 120 | 1 | 65.0 | 32.49 | 3 | ||||

| 6 | T06 | Gcoba ngokuhlanekezela futhi ngokunembile ubuso bokuphela obuphansi | 390.00 | 450 | 367 | 0.25 | 92 | 1 | 65.0 | 42.45 | 3 | ||||

| Incazelo: | Isikhathi sokusika: | 437 | Okwesibili | Isikhathi sokubopha nge-fixture kanye nokulayisha nokuvala izinto: | 15.00 | Okwesibili | |||||||||

| Isikhathi sokusiza: | 21 | Okwesibili | Isamba samahora omuntu wokwenza imishini: | 472.81 | Okwesibili | ||||||||||

| OP20 machining Cycle timer | |||||||||||||||

| Incazelo yomzila |  | ||||||||||||||

| Ikhasimende | Impahla yokusebenza | HT250 | Imodeli yethuluzi lomshini | Inombolo yomlando | |||||||||||

| Igama Lomkhiqizo | Ibhuleki isigubhu | Umdwebo No. | Usuku lokulungiselela | 2021.1.19 | Ilungisiwe ngu | ||||||||||

| Isinyathelo sokucubungula | Ummese No. | okuqukethwe komshini | Igama Lethuluzi | Ukusika Ububanzi | Ukusika isivinini | Isivinini sokujikeleza | Okuphakelayo ngokwenguquko ngayinye | ukudla ngethuluzi lomshini | Inombolo yokusika | Inqubo ngayinye | Isikhathi somshini | Isikhathi Sokungenzi lutho | Qinisa futhi uxege | Isikhathi sokushintsha ithuluzi | |

| Cha. | Cha. | I-Desorptions | Amathuluzi | D mm | VcM/min | R pm | mm/Rev | mm/Miniz | Izikhathi | Ubude mm | Isiqephu | Isiqephu | Isiqephu | ||

| 1 | T01 | Geza imbobo engu-10-DIA 23.5 | I-Down-the-hole drill DIA 23.5 | 23.50 | 150 | 2033 | 0.15 | 305 | 10 | 15.0 | 29.52 | 20 | 5 | ||

| 2 | T04 | 10-DIA 23 Orifice Chamfering | I-DIA 30 i-compound reaming chamfering cutter | 30.00 | 150 | 1592 | 0.20 | 318 | 10 | 3.0 | 6.65 | 20 | 5 | ||

| 3 | T06 | 10-DIA 23.5 Back orifice chamfering | I-DIA 22 i-reverse chamfering cutter | 22.00 | 150 | 2171 | 0.20 | 434 | 10 | 3.0 | 4.14 | 40 | 5 | ||

| 4 | T08 | Indawo Yokumaka Yokugaya | I-DIA engu-30 square milling yehlombe | 30.00 | 80 | 849 | 0.15 | 127 | 1 | 90.0 | 42.39 | 4 | 5 | ||

| Incazelo: | Isikhathi sokusika: | 82 | Okwesibili | Isikhathi sokubopha nge-fixture kanye nokulayisha nokuvala izinto: | 30 | Okwesibili | |||||||||

| Isikhathi sokusiza: | 104 | Okwesibili | Isamba samahora omuntu wokwenza imishini: | 233.00 | Okwesibili | ||||||||||

Isingeniso Kulayini Wokukhiqiza

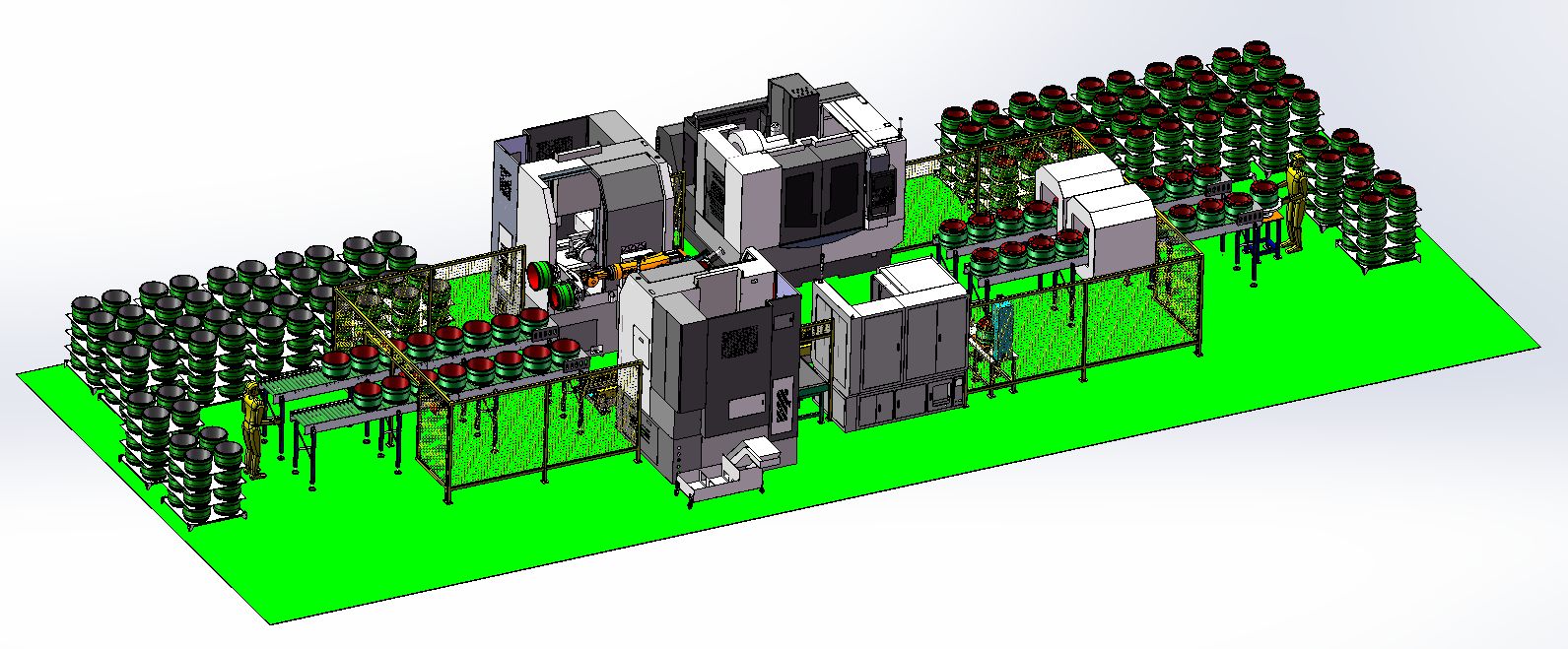

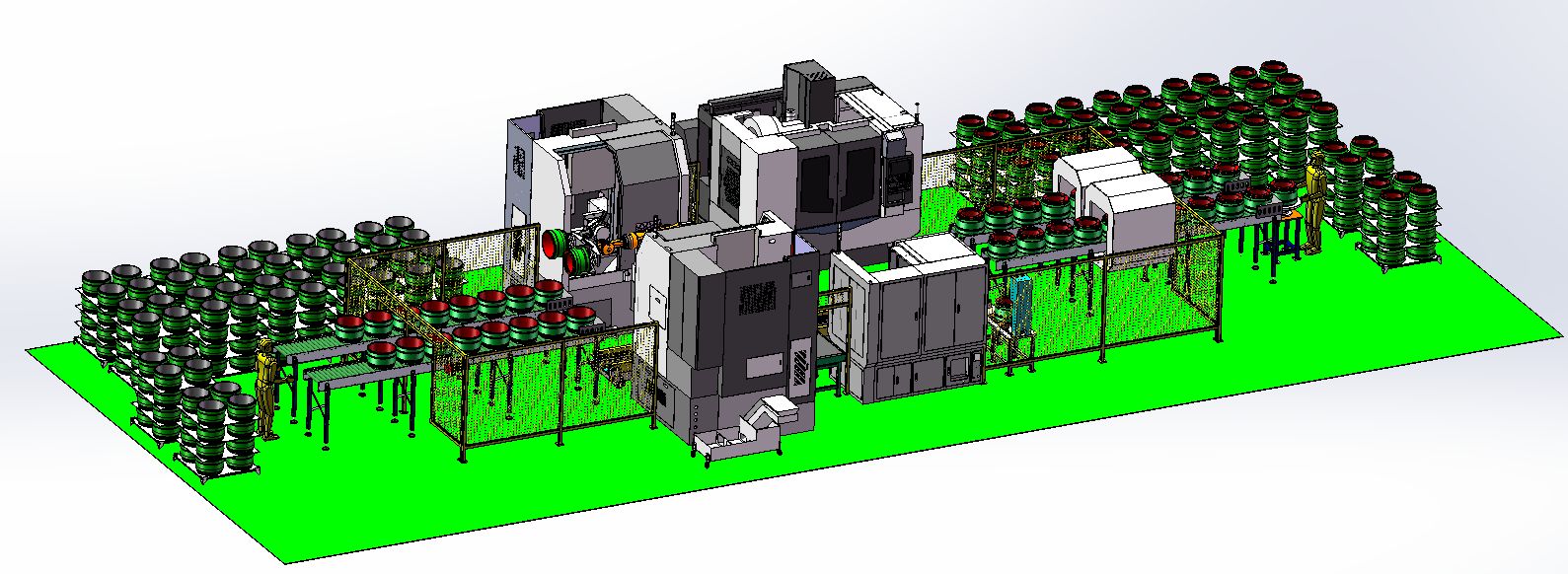

Isakhiwo Solayini Wokukhiqiza

Isingeniso Kulayini Wokukhiqiza

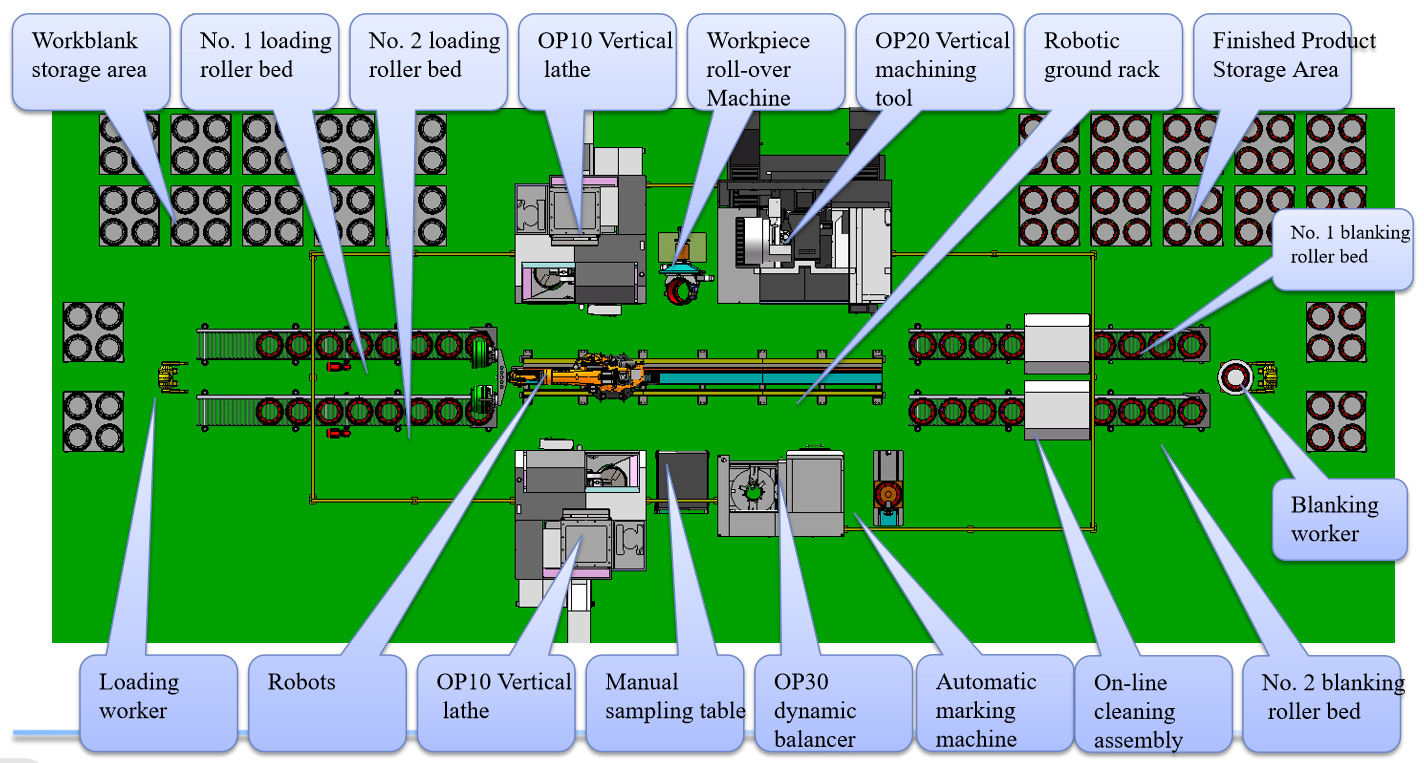

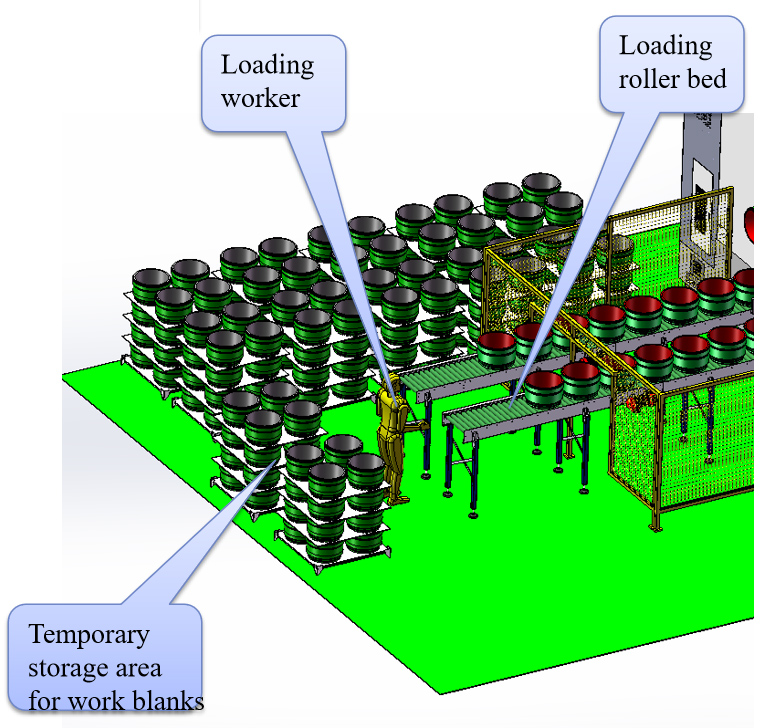

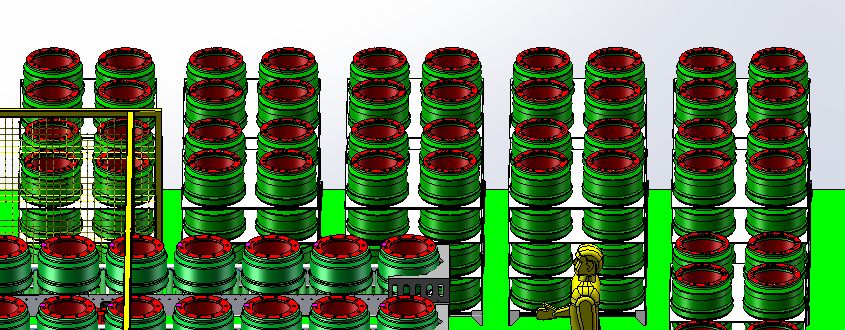

Ulayini wokukhiqiza uqukethe iyunithi yokulayisha engu-1, iyunithi yomshini we-lathe engu-1 kanye neyunithi eyodwa engenalutho. Izinto zokuthutha amarobhothi phakathi kweziteshi ngaphakathi kweyunithi ngayinye. Ama-Forklift abeka obhasikidi phambi kwamayunithi okulayisha nawokungenalutho; Ulayini wokukhiqiza uhlanganisa indawo: 22.5m×9m

Incazelo yomugqa wokukhiqiza

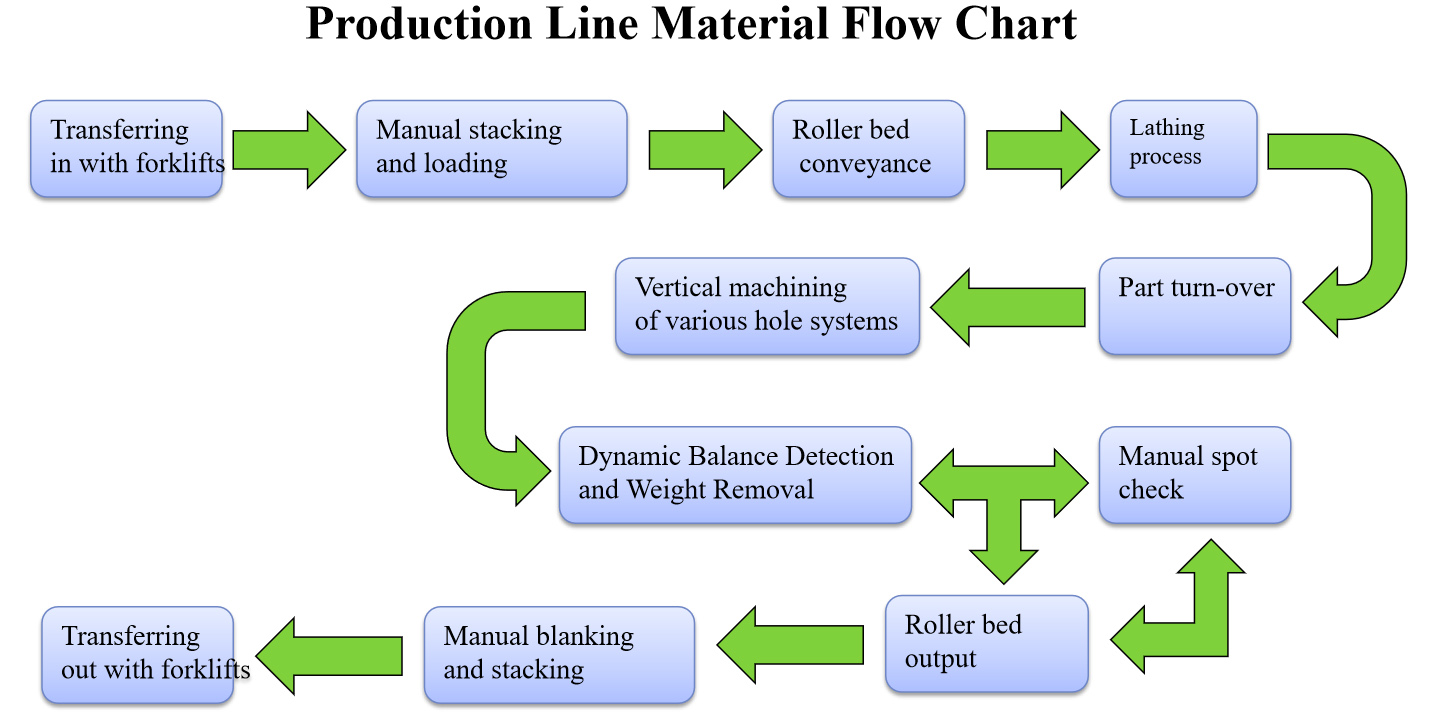

1. Izikhala zomsebenzi zithuthelwa eziteshini zokulayisha ngama-forklift, ziphakanyiswe ngesandla kumbhede we-roller, futhi zithunyelwa eziteshini zokulayisha ngokusebenzisa ama-roller. Ukulayishwa nokukhishwa komshini wokulinganisa enqubweni ye-lathe, inqubo ye-roll-over kanye nenqubo yokubhoboza nokugaya kuqedwa ngamarobhothi. Imikhiqizo eqediwe ithunyelwa eziteshini ezingenalutho ngokusebenzisa umbhede we-roller, futhi ithunyelwe ngama-forklifts ngemuva kokuphakanyiswa nokupakisha ngesandla;

2. Izikrini ezinkulu zokubonisa zikagesi zizosethwa emigqeni yokuhambisa izinto ukuze zibuyekeze futhi zibonise ulwazi lokuphumayo, imikhiqizo enesici kanye nezinsuku zokukhiqiza zokuphepha ngesikhathi sangempela;

3. Ulayini wokudlulisa uzohlinzekwa ngokukhanya okuyisixwayiso kuyunithi ngayinye, engabonisa ulwazi olufana nolwejwayelekile, ukungabi bikho kwezinto kanye nokuthusayo;

4. Ulayini ozenzakalelayo wamukela imodi yeyunithi yokucutshungulwa kanye nemodi yezintambo eziningi, enesakhiwo esivumelana nezimo, esilungele izidingo ezihlukene zesakhiwo samakhasimende;

5. Yamukela irobhothi elihlanganyelwe ukuze lilayishwe futhi livalwe, elinozinzo oluphezulu, ukugcinwa okulula nempilo ende yesevisi;

6. Isidingo esincane sabasebenzi. Isidingo sansuku zonke sabasebenzi sokushintsha ngakunye kwalo mugqa ozenzakalelayo simi kanje:

I-Forkliftman 1 ~ 2 abantu (abaphethe ukuphakamisa, ukuphakamisa i-forklift nokudlulisa izikhala zomsebenzi / imikhiqizo eqediwe)

Unjiniyela Wezokulungisa umuntu ongu-1 (ophethe ukunakekela okujwayelekile-abasiki bakawoyela namanzi, njll.)

7. Ulayini ozenzakalelayo unokunwebeka okuqinile. Okufana nokuxutshwa kocingo okuxubile, ukulandeleka kocezu lokusebenza neminye imisebenzi, enezindleko eziphansi zokunwetshwa;

Ilayisha iyunithi

1. I-roller bed yokulayisha ingagcina izingcezu ezingu-12×16=192; 2. Vula isitaki mathupha bese usiphakamisela embhedeni we-roller olayishayo bese usithumela esiteshini sokulayisha ngomthumeli we-roller; 3. Ngemva kokuvula isitaki, ithreyi elingenalutho liyoboshelwa futhi libekwe emgqeni ongenalutho wamathileyi angenalutho, anqwabelene abe yizingqimba eziyi-8, futhi ukunqwabelana kwethreyi elingenalutho kuzosuswa ngesandla kubekwe endaweni yokugcina;1. I-roller bed yokulayisha ingagcina izingcezu eziyi-12×16=192;

2. Vula isitaki mathupha bese usiphakamisela embhedeni we-roller olayishayo bese usithumela esiteshini sokulayisha ngomthumeli we-roller;

3. Ngemva kokuvula isitaki, ithreyi elingenalutho liyoboshelwa futhi libekwe emgqeni ongenalutho wamathreyi angenalutho, ahlanganiswe zibe izingqimba ezingu-8, futhi ukupakishwa kwethreyi engenalutho kuzosuswa ngesandla futhi kubekwe endaweni yokugcina;

Isingeniso sokusebenza izitaki ezingenalutho

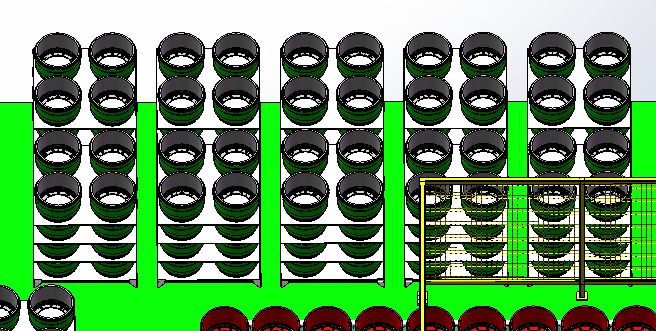

1. Isitaki esisodwa sezingcezu eziyi-16 nezingqimba ezi-4 sezizonke, namapuleti okuhlukanisa phakathi kongqimba ngalunye;

2. Isitaki esingenalutho somsebenzi singagcina izingcezu eziyi-160;

3. Iphalethi liphakanyiswa ukuthi lilungiswe yikhasimende. Isidingo: (1) Ukuqina okuhle nokuthambile (2) ukukwazi ukucindezelwa irobhothi.

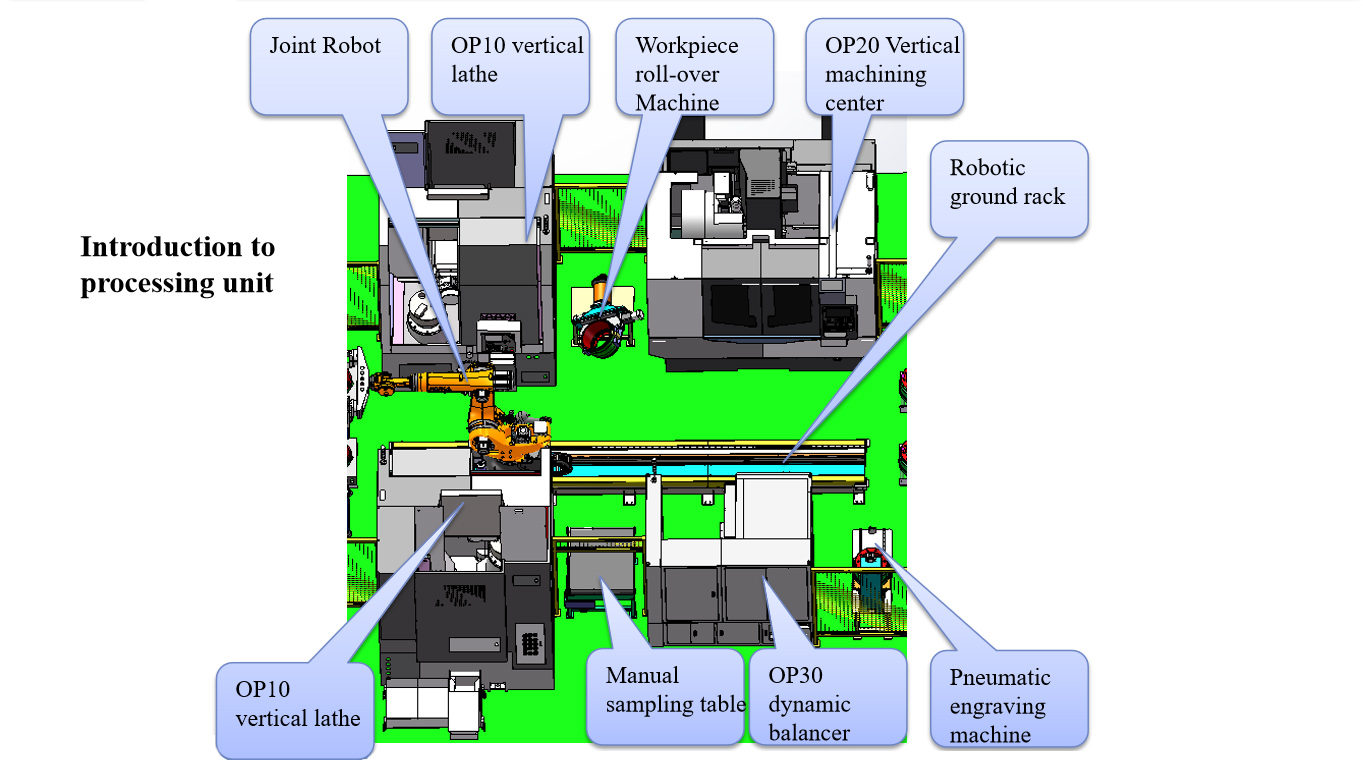

Isingeniso seyunithi yokucubungula

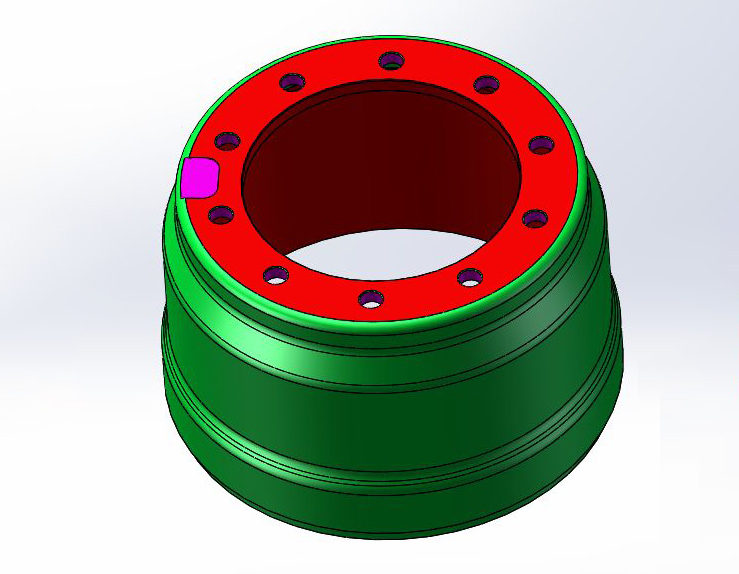

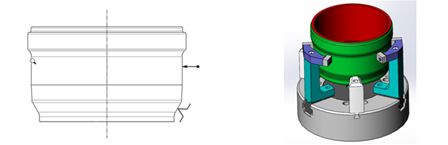

1. Inqubo ye-lathing iqukethe ama-lathe amabili aqondile, irobhothi elinguNombolo 1 kanye ne-robot ground rack, eyenza machining of indilinga yangaphandle, indawo yesinyathelo sembobo engaphakathi kanye nobuso bokuphela bengxenye;

2. Isiteshi esiginqikayo sinomshini owodwa oginqikayo, owenza izingxenye eziginqikayo;

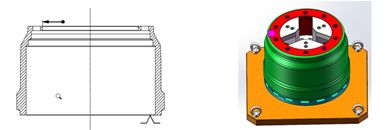

3. Inqubo yokubhoboza nokugaya iqukethe isikhungo semishini esime mpo esi-1 kanye nerobhothi elingu-No. 2, elenza umshini wokufaka imbobo kanye nendawo yokumaka yale ngxenye.

4. Ukulinganisa okuguquguqukayo kanye nenqubo yokususa isisindo iqukethe ibhalansi eguqukayo eqondile, eyenza ukutholwa kokulinganisa okuguquguqukayo kanye nokususa isisindo sezingxenye;

5. Isiteshi sokuhlola indawo okwenziwa ngaso ngesandla siqukethe i-conveyor yebhande, ehambisa izingxenye ezihlolwe indawo futhi isetshenziswe njengendawo yokuhlola;

6. Isiteshi sokusebenza somshini wokudweba umoya we-pneumatic senza umsebenzi wokuqopha nokumaka yonke imikhiqizo;

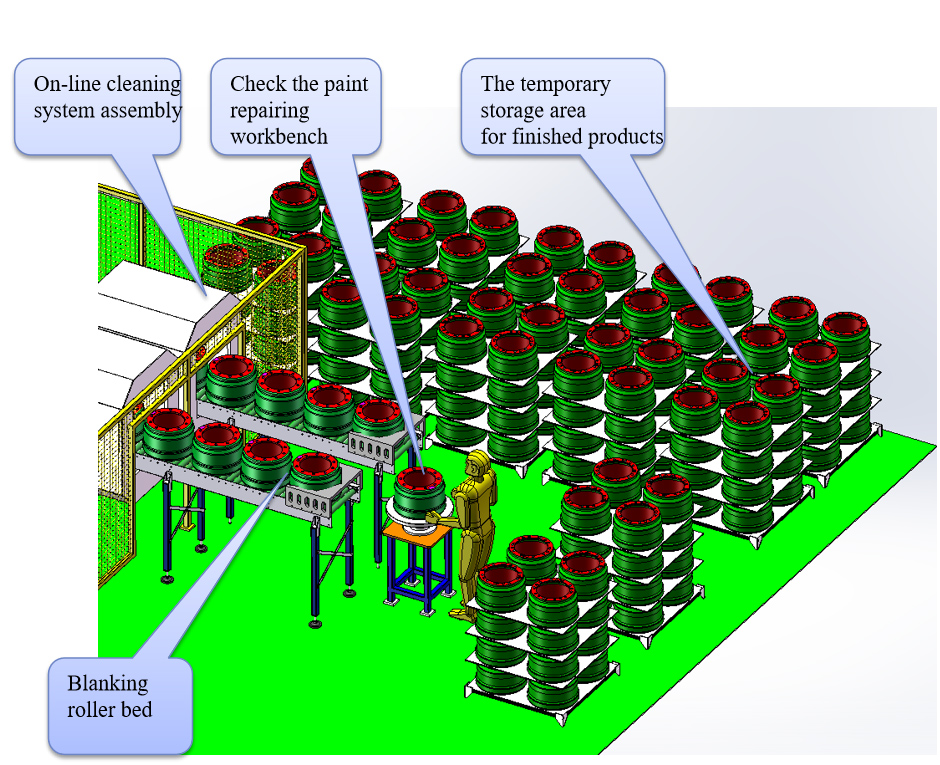

Ukwethulwa kweyunithi engenalutho

1. I-roller bed yokulayisha ingagcina izingcezu ezingu-12×16=192;

2. Amathreyi nama-partition plate esiteshini sokulayisha ayiswa endaweni engenalutho ngama-forklift;

3. Imikhiqizo eqediwe ithuthwa iyiswa esiteshini esingenalutho nge-roller conveyor, futhi iphakanyiswe futhi ipakishwe ngesandla bese idluliswa ngama-forklift;

Ukwethulwa kokupakishwa komkhiqizo oqediwe

1. Isitaki esisodwa sezingcezu eziyi-16 nezingqimba ezi-4 sezizonke, namapuleti okuhlukanisa phakathi kongqimba ngalunye;

Izingcezu ezingu-2.192 zingagcinwa kunqwaba yemikhiqizo eqediwe;

3. Iphalethi liphakanyiswa ukuthi lilungiswe yikhasimende. Isidingo: (1) Ukuqina okuhle nokuthambile (2) ukukwazi ukucindezelwa irobhothi.

Ukwethulwa kwezingxenye eziyinhloko zokusebenza komugqa wokukhiqiza

Isingeniso se-Machining and Dynamic Balancing Weight Removal Unit Robot

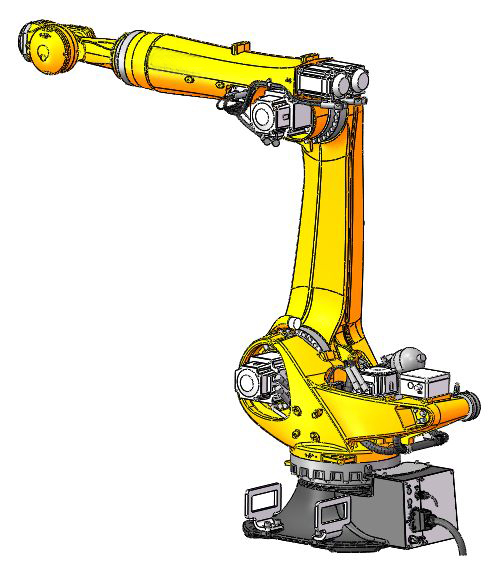

Irobhothi le-Chenxuan: SDCX-RB08A3-1700

| Idatha eyisisekelo | |

| Uhlobo | I-SDCX-RB08A3-1700 |

| Inombolo yezimbazo | 6 |

| Ukufakwa okuphezulu | 3100 mm |

| Ukuphindaphinda kokuma (ISO 9283) | ±0.05mm |

| Isisindo | 1134kg |

| Isigaba sokuvikela irobhothi | Isilinganiso sokuvikela, IP65 / IP67isihlakala esisemgqeni(IEC 60529) |

| Indawo yokukhweza | Uphahla, i-engeli evumelekile yokuthambekela ≤ 0º |

| Ukuphela kwendawo, umsebenzi wokupenda | Uhlaka oluyisisekelo: olumnyama (RAL 9005) |

| Izinga lokushisa le-ambient | |

| Ukusebenza | 283 K kuya ku-328 K (0 °C kuya +55 °C) |

| Isitoreji kanye nezinto zokuhamba | 233 K kuya ku-333 K (-40 °C kuya +60 °C) |

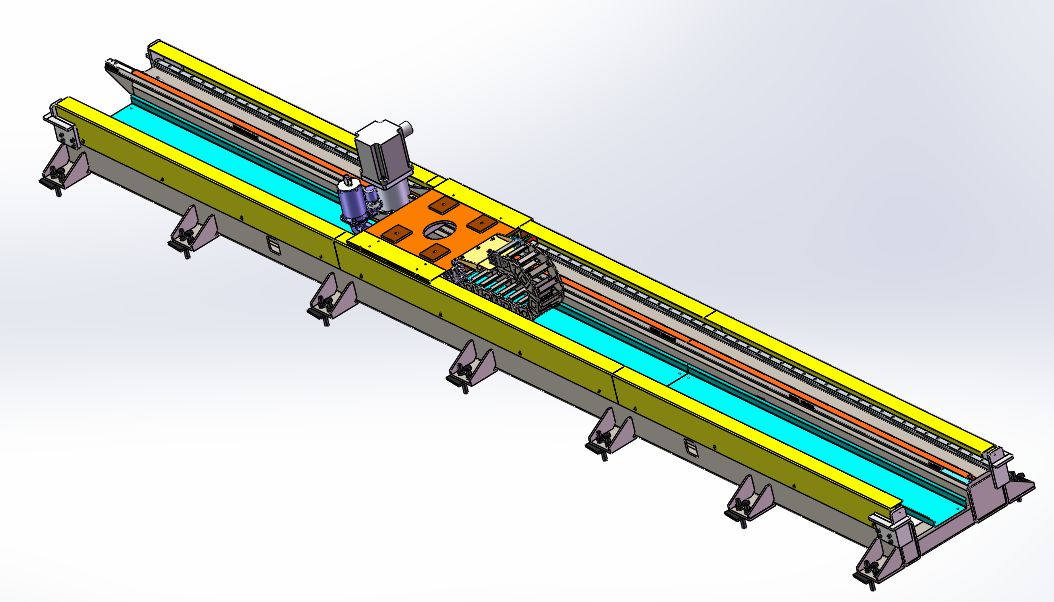

Ukwethulwa kwe-Robot Travel Axis

Isakhiwo sakhiwe irobhothi elihlanganyelwe, i-servo motor drive kanye ne-pinion ne-rack drive, ukuze irobhothi likwazi ukwenza ukunyakaza kwe-rectilinear emuva naphambili. Ibona umsebenzi werobhothi elilodwa elinikeza amathuluzi emishini eminingi kanye nezinto zokusebenza ezibambayo eziteshini eziningana futhi lingandisa ukumbozwa kokusebenza kwamarobhothi ahlangene;

Ithrekhi yokuhamba isebenzisa isisekelo esishiselwe ngamapayipi ensimbi futhi ishayelwa yi-servo motor, pinion kanye ne-rack drive, ukwandisa ukumboza ukusebenza kwerobhothi elihlanganyelwe futhi kuthuthukiswe ngempumelelo izinga lokusetshenziswa kwerobhothi;

Ithrekhi yokuhamba ifakwe phansi;

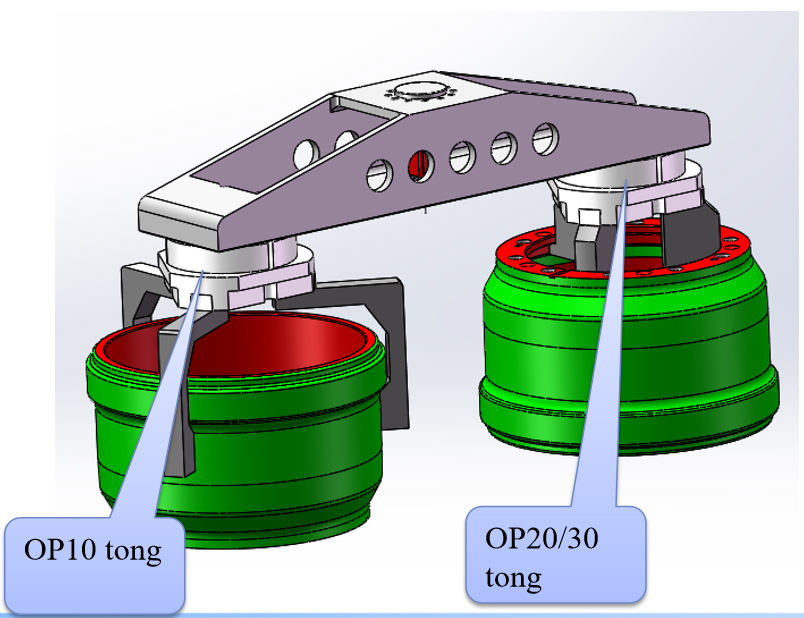

Ukwethulwa kwezindlawu zokulayisha kanye namarobhothi angenalutho

Incazelo:

1. Ngokwezici zale ngxenye, sithatha indawo yamagagasi yangaphandle enezinzipho ezintathu;

2. Umshini ufakwe inzwa yokubona indawo kanye nenzwa yokucindezela ukuze ibone ukuthi isimo sokugoqa kanye nokucindezela kwezingxenye kujwayelekile;

3. Umshini ufakwe i-pressurizer, futhi i-workpiece ngeke siwe ngesikhathi esifushane uma kwenzeka ukwehluleka kwamandla kanye nokunqanyulwa kwegesi kumjikelezo womoya omkhulu;

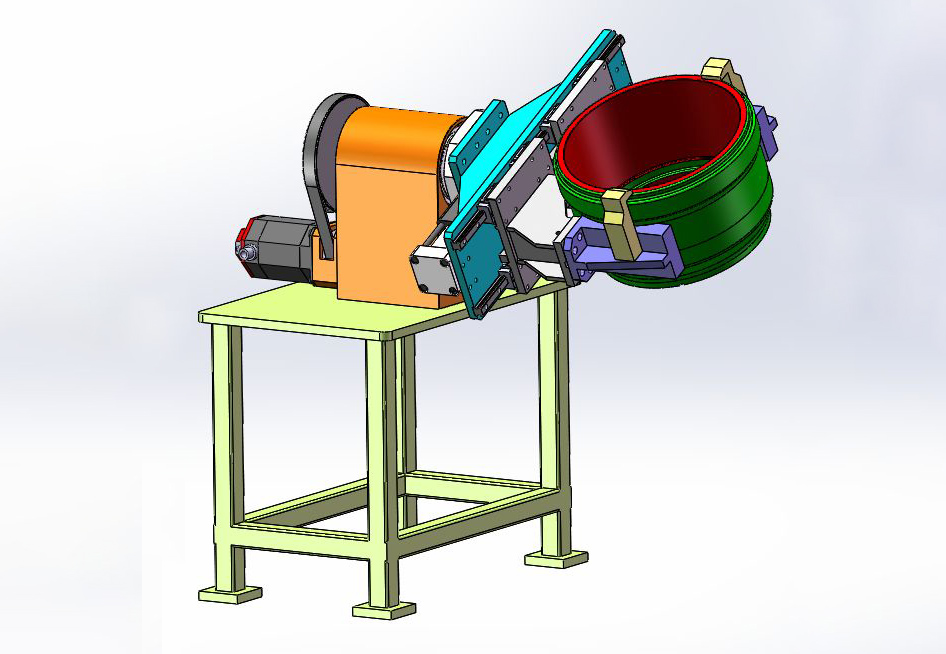

Ukwethulwa komshini ozenzakalelayo wokugoqa

Incazelo:

Umshini wakhiwe ngohlaka olungaguquki, umhlangano wesisekelo sokusekela kanye nomhlangano wethongo womoya. Inomsebenzi wokunqanda ukuxega kanye nokuwisa ngemva kokunqamuka komoya, futhi ingakwazi ukubona ukugoqeka okungu-180° komugqa womsebenzi;

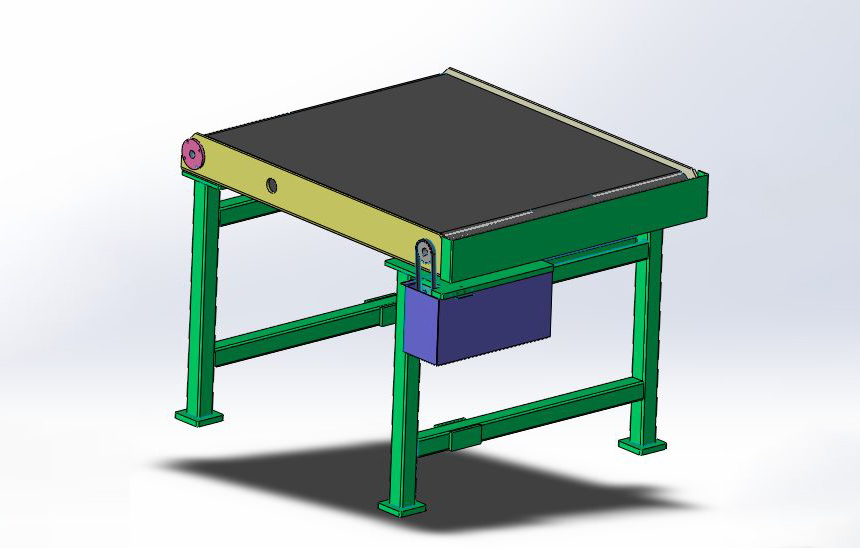

Isingeniso ebhentshini lokuhlola indawo okwenziwa ngesandla

Incazelo:

1. Setha imvamisa yesampula engahleliwe yemanuwali ehlukene yezigaba zokukhiqiza ezihlukene, ezingagada ngempumelelo ukuphumelela kokulinganisa ku-inthanethi;

2. Imiyalelo Yokusetshenziswa: I-manipulator izobeka ucezu lokusebenza endaweni emisiwe ebhentshini lokuhlola indawo ngokuya ngefrikhwensi esethwe ngesandla, futhi ikhanyise ngesibani esibomvu. Umhloli uzocindezela inkinobho yokuthutha i-workpiece endaweni yokuphepha ngaphandle kwesivikelo, akhiphe i-workpiece ukuze alinganise futhi ayibuyisele embhedeni we-roller ngemva kokulinganisa;

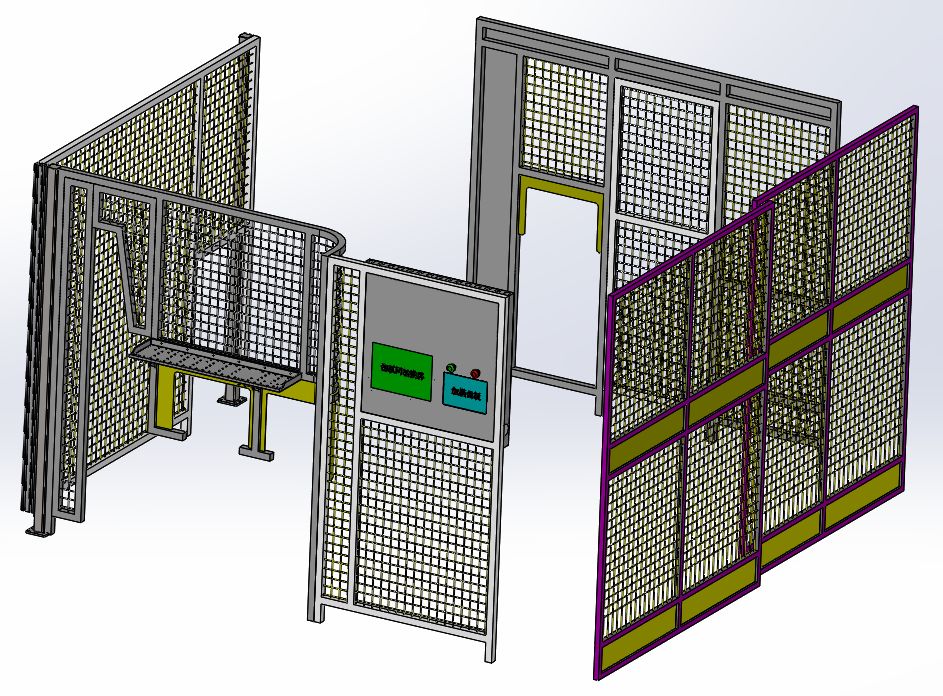

Izingxenye zokuzivikela

Yakhiwe ngephrofayela ye-aluminium engasindi (40×40)+mesh (50×50), futhi isikrini sokuthinta kanye nenkinobho yokumisa izimo eziphuthumayo ingahlanganiswa nezingxenye zokuzivikela, ihlanganise ukuphepha nobuhle.

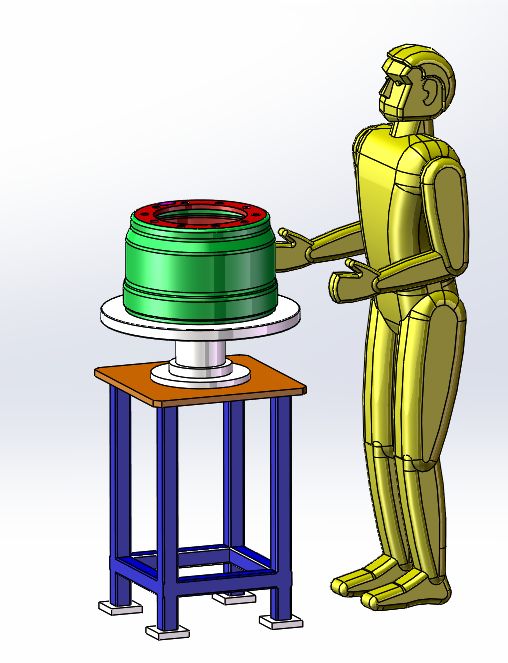

Isingeniso Esiteshini Sokuhlola ukuze kulungiswe upende

Incazelo:

Umshini wakhiwe ngohlaka olungaguquki kanye ne-turntable. Abasebenzi baphakamisela imikhiqizo eqediwe kuyi-turntable, bazungezisa i-turntable, bahlole ukuthi akhona yini amaqhubu, imihuzuko nezinye izenzakalo, futhi balungise ngesikhathi amaphutha aqhumayo kanye nendawo kapende;