Izidingo zephrojekthi

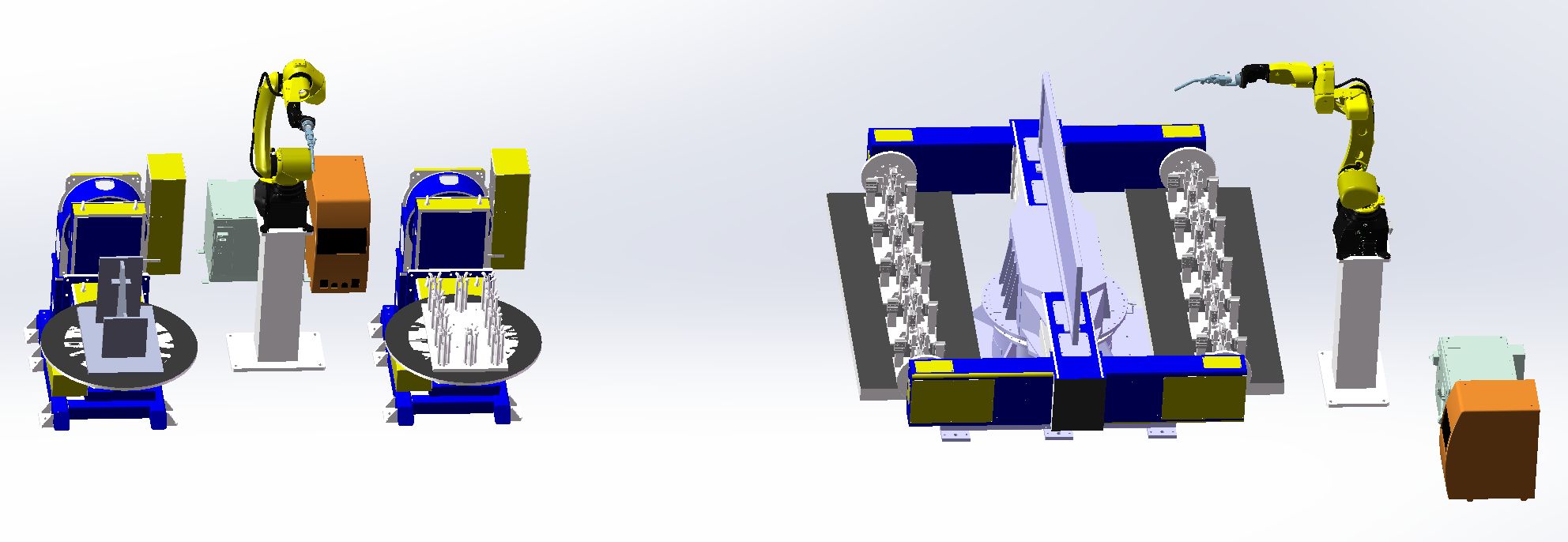

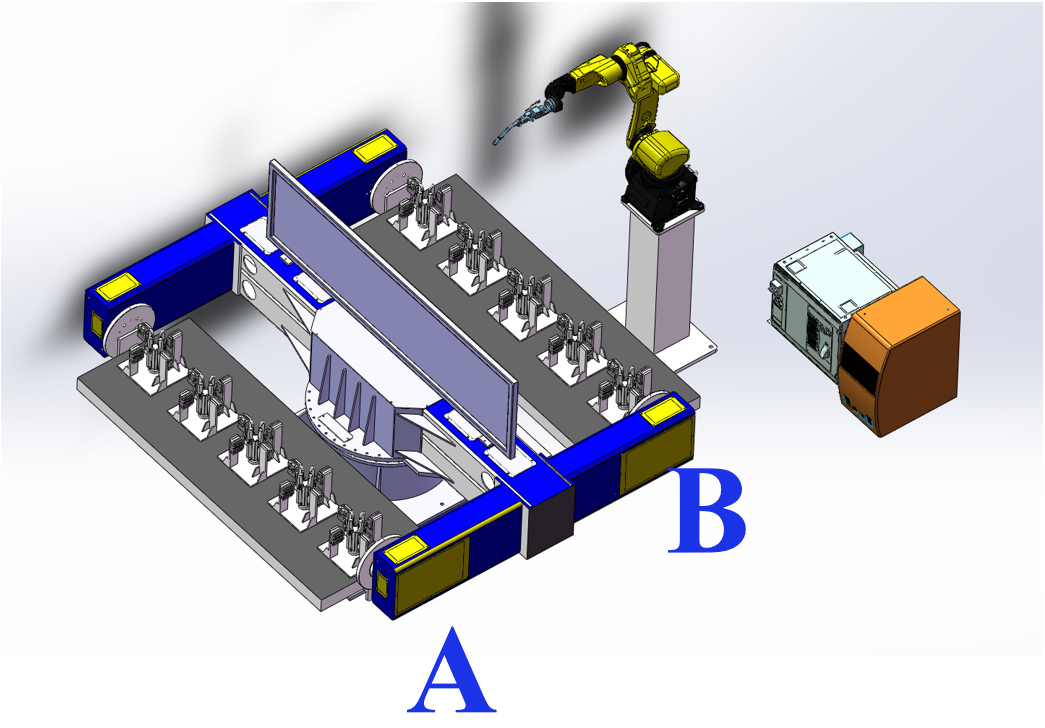

Sekukonke Isakhiwo&3D Model

Qaphela: Umdwebo weskimu usetshenziselwa kuphela umdwebo wesakhiwo futhi awumeli isakhiwo esibonakalayo sempahla. Usayizi othize uzonqunywa ngokuya ngezimo zesayithi yekhasimende.

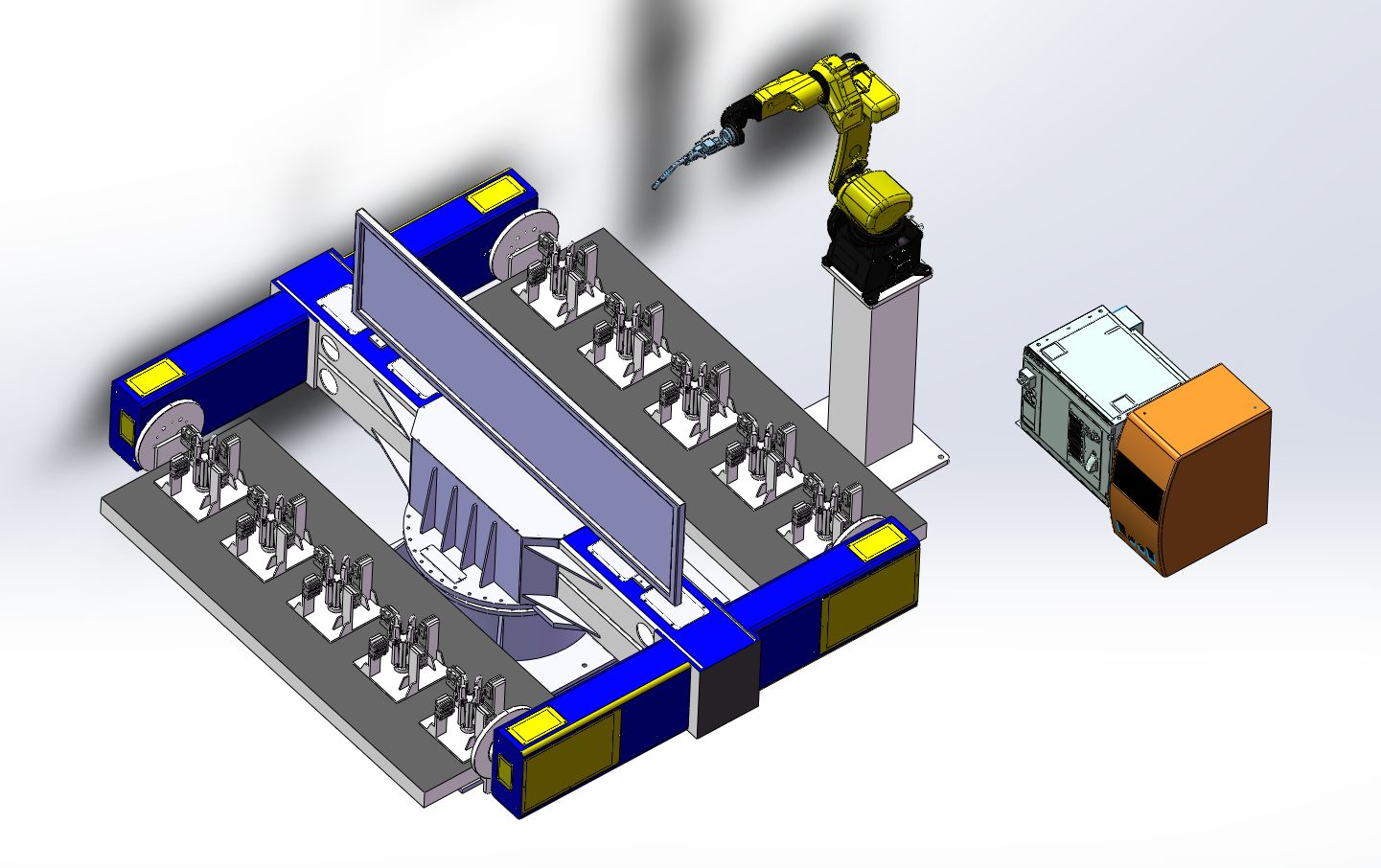

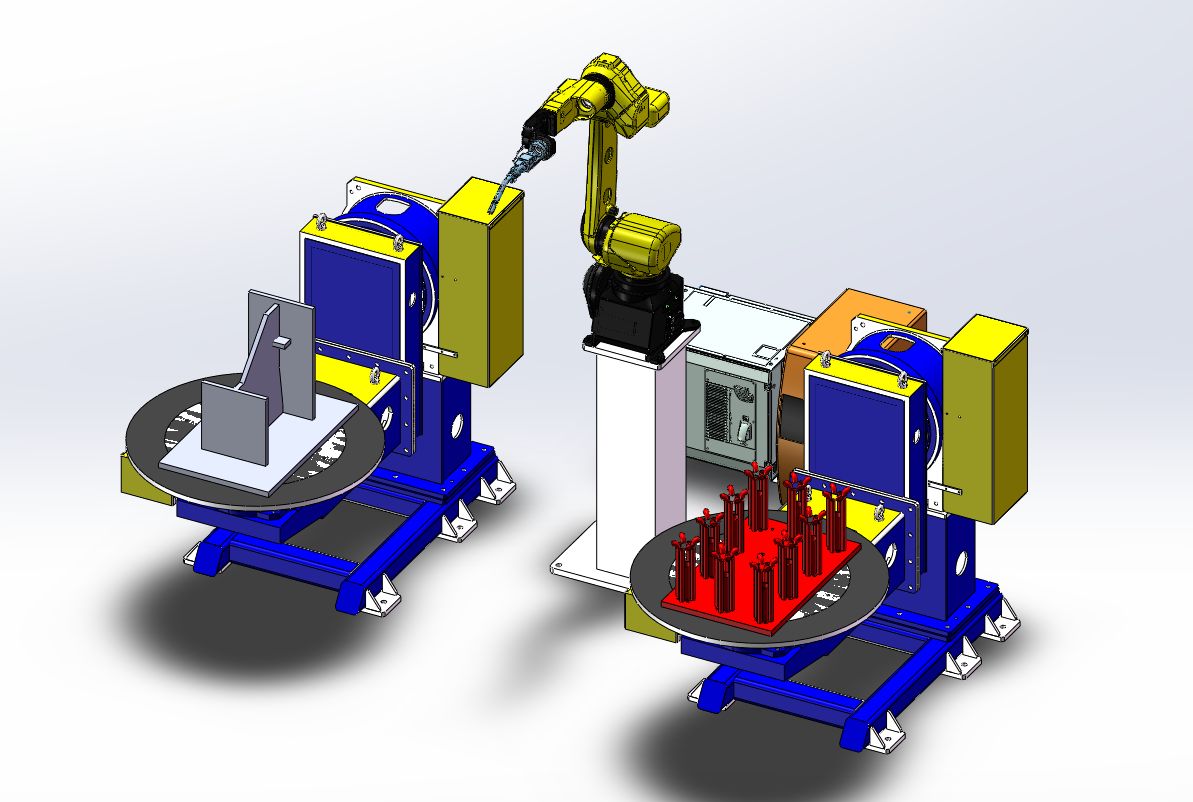

Umdwebo obonakalayo we-Workpiece nemodeli ye-3D

Umdwebo obonakalayo we-Workpiece nemodeli ye-3D

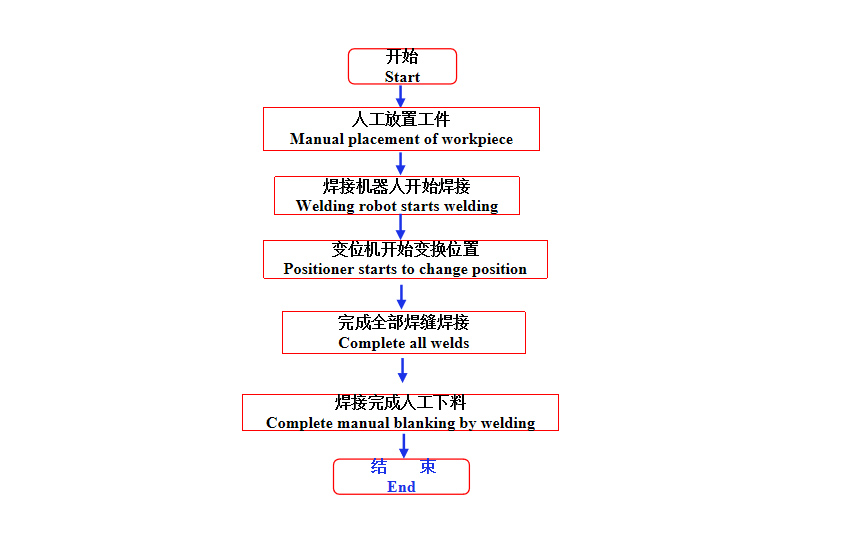

Ukuhamba komsebenzi

Imibandela yokusebenza kwendawo yokusebenza

(1) Beka i-workpiece endaweni bese uyilungisa ngokwezidingo.

(2) Ngemuva kokuthi wonke amadivaysi avuliwe futhi akukho alamu eboniswayo, lungiselela ukufakwa.

(3) Irobhothi liyama endaweni eyimvelaphi yomsebenzi, futhi uhlelo olusebenzayo lwerobhothi wuhlelo lokukhiqiza oluhambisanayo.

Inqubo ye-Welding ye-sleeve subassembly

1. Faka mathupha amasethi amahlanu ezingxenye zemikhono ohlangothini A.

2. Buyela mathupha endaweni yokuphepha bese uqala inkinobho yesilinda sokuqinisa ukuze uqinise isiqephu sokusebenza.

3. Isibonisi siyazungeza kuze kube yilapho irobhothi elikuhlangothi B liqala ukushisela.

4. Yehlisa ngokuzenzela izinto zokusebenza ezishiselwe ohlangothini A, bese kuba amasethi amahlanu ezingxenye zesigubhu.

5. Biyela ukusebenza kwalezi zixhumanisi ezingenhla.

Isikhathi sokushisela sesethi ngayinye yemikhono yi-3min (kuhlanganise nesikhathi sokufaka), futhi isikhathi sokushisela samasethi angu-10 yi-30min.

Inqubo yokushisela yokuhlanganisa ipuleti elishumekiwe + umhlangano wemikhono

1. Faka mathupha ipuleti elishumekiwe elikhombe ngaphambili endaweni yohlobo lwe-L ohlangothini A.

2. Qala inkinobho yerobhothi welding embedded plate assembly (15min/set). 3.

3. Faka mathupha izingxenye ezixegayo zokuhlanganisa imikhono endaweni yohlobo lwe-L ohlangothini B.

4. Irobhothi liyaqhubeka nokushisela ukuhlanganiswa kwemikhono ngemva kokushisela ukuhlanganiswa kwepuleti elishumekiwe(i-sleeve welding for 10min+ukufakwa ngesandla kwe-workpiece kanye nokushisela indawo irobhothi imizuzu emi-5)

5. Khipha umhlangano wepuleti elishumekiwe mathupha.

6. Welding mathupha yokuhlanganisa ipuleti embedded (ukukhipha-spot welding-loading phakathi 15min)

7. Faka mathupha ipuleti elishumekiwe elikhombe ngaphambili endaweni yohlobo lwe-L ohlangothini A.

8. Susa umhlangano wemikhono oshiselwe bese ufaka izingxenye ezisele

9. Biyela ukusebenza kwezixhumanisi ezingenhla.

Isikhathi sokuqeda ukushisela kwepuleti elishumekiwe yi-15min + isikhathi sokuqeda ukushisela sokuhlanganiswa kwemikhono yi-15min.

Isikhathi esiphelele 30min

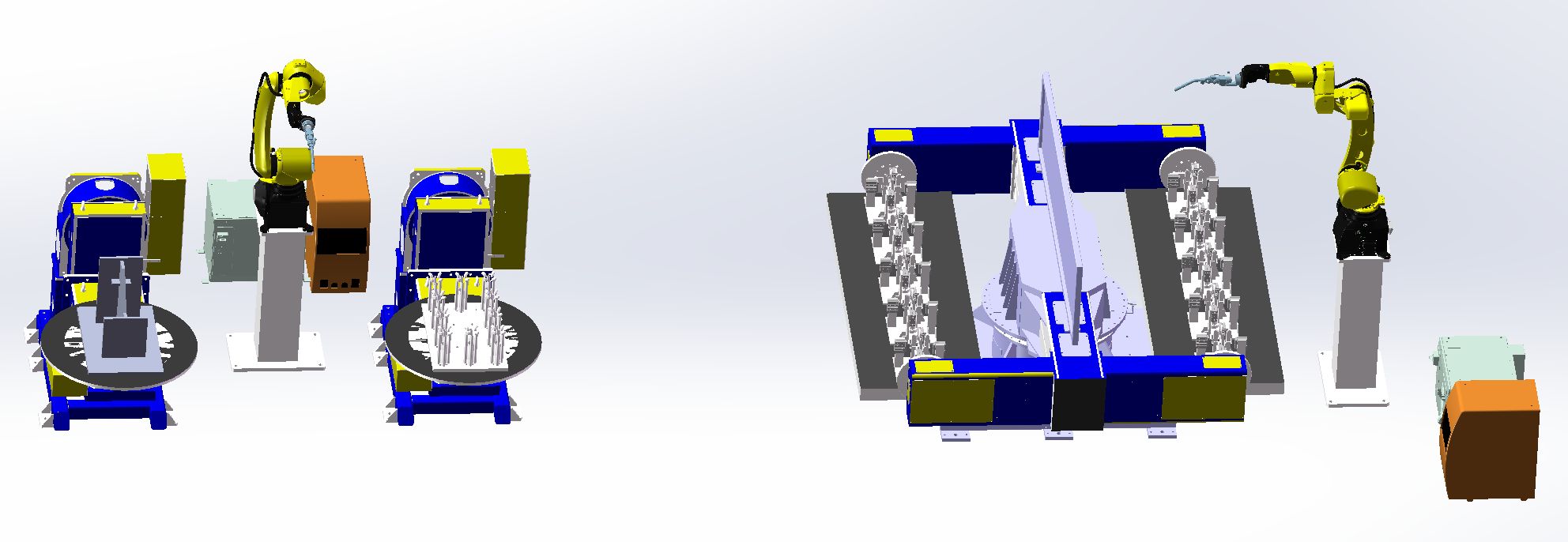

Ukwethulwa kwe-Tong Changing Device

Isikhathi sokushisela irobhothi kulesi sigqi esishiwo ngenhla yisona esanele kakhulu ngaphandle kokuma. Ngokusho kwamahora angu-8 ngosuku kanye nabaqhubi ababili, ukukhishwa kwemihlangano emibili kuhlanganisa amasethi angama-32 ngosuku.

Ukwandisa okukhiphayo:

Irobhothi elilodwa lengezwa endaweni yokumisa ama-eksisi amathathu esiteshini se-sleesembly subassembly futhi lishintshelwe ekushiseleni kwemishini ekabili. Ngesikhathi esifanayo, isiteshi sokuhlanganisa imikhono yamapuleti ashumekiwe+ sidinga ukungeza amasethi amabili esimo sohlobo lwe-L nesethi eyodwa yerobhothi. Ngosuku lwamahora angu-8 kanye nesisekelo sabasebenzi abathathu, ukukhishwa kwemihlangano emibili kuhlanganisa amasethi angu-64 ngosuku.

Uhlu Lwezisetshenziswa

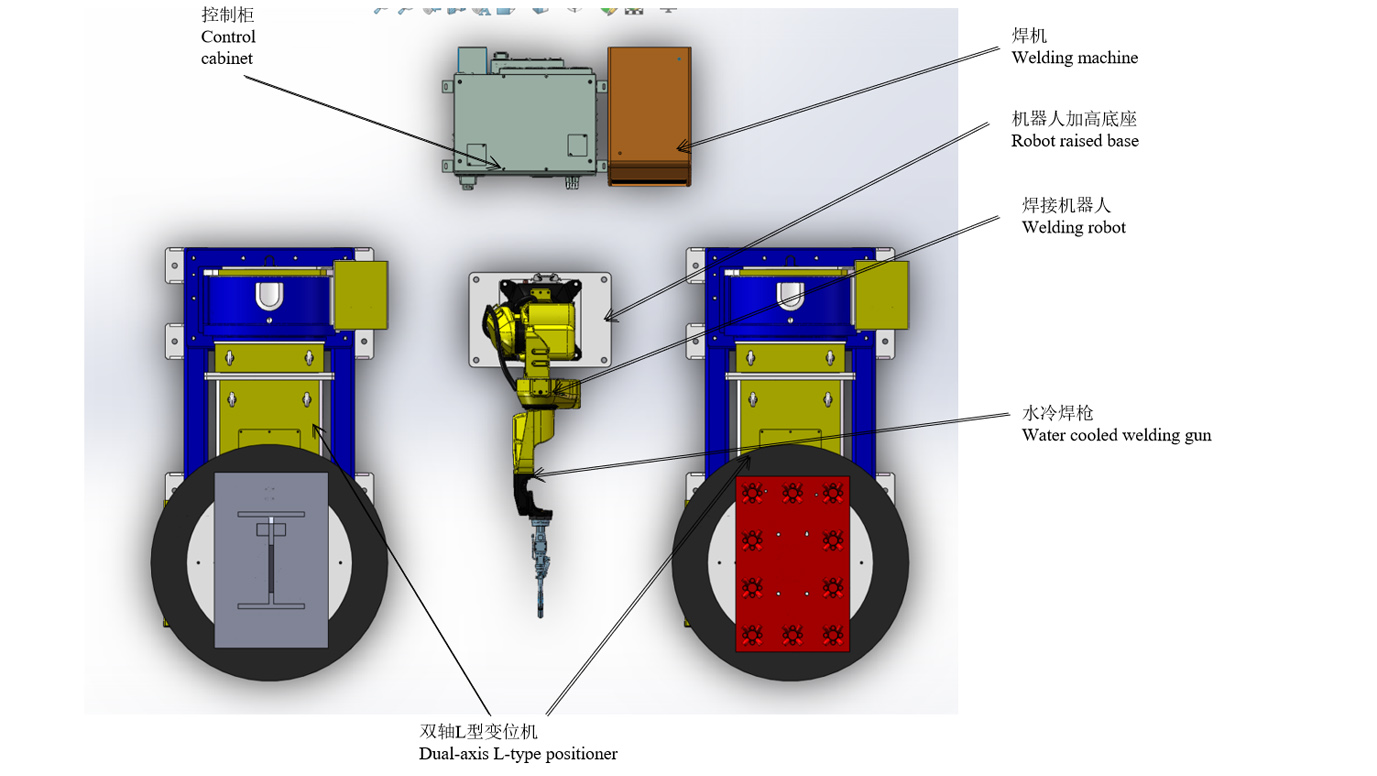

| Into | I-S/N | Igama | Qty. | AMAZWI |

| Amarobhothi | 1 | I-RH06A3-1490 | 2 amasethi | Kunikezwe ngu-Chen Xuan |

| 2 | Ikhabethe lokulawula amarobhothi | 2 amasethi | ||

| 3 | Isisekelo serobhothi esiphakanyisiwe | 2 amasethi | ||

| 4 | Isibhamu se-welding samanzi esipholile | 2 amasethi | ||

| Imishini ye-peripheral | 5 | Umthombo wamandla we-Welding MAG-500 | 2 amasethi | Kunikezwe ngu-Chen Xuan |

| 6 | Isikhundla sohlobo lwe-Dual-eksisi L | 2 amasethi | ||

| 7 | Isibonisi esijikelezayo esinama-eksisi amathathu | 1 isethi | Kunikezwe ngu-Chen Xuan | |

| 8 | Ukulungisa | 1 isethi | ||

| 9 | Isicoci sezibhamu | Setha | Ongakukhetha | |

| 10 | Imishini yokukhipha uthuli | 2 amasethi | ||

| 11 | Ucingo lokuphepha | 2 amasethi | ||

| Isevisi Ehlobene | 12 | Ukufakwa kanye nokugunyazwa | 1 into | |

| 13 | Ukupakisha kanye Nezokuthutha | 1 into | ||

| 14 | Ukuqeqeshwa kobuchwepheshe | 1 into |

Ukucaciswa Kwezobuchwepheshe

Isibhamu sokushisela esakhelwe ngaphakathi esipholiswe ngamanzi

1) Isibhamu ngasinye sokushisela sizodlula ekukalweni kwe-ternary ukuqinisekisa ukunemba kobukhulu;

I-2) Ingxenye ye-R yesibhamu sokushisela yenziwa ngendlela yokukhipha i-wax emanzi, engeke ikhubazeke ngenxa yokushisa okuphezulu okukhiqizwa ukushisela;

3) Ngisho noma isibhamu sokushisela singqubuzana ne-workpiece kanye ne-fixture ngesikhathi sokusebenza, isibhamu sokushisela ngeke sigobe futhi akukho ukulungiswa kabusha okudingekayo;

4) Thuthukisa umphumela wokulungisa wegesi evikelayo;

5) Ukunemba komgqomo owodwa kungaphakathi kwe-0.05;

6) Isithombe ngesethenjwa kuphela, futhi singaphansi kokukhethwa kokugcina.

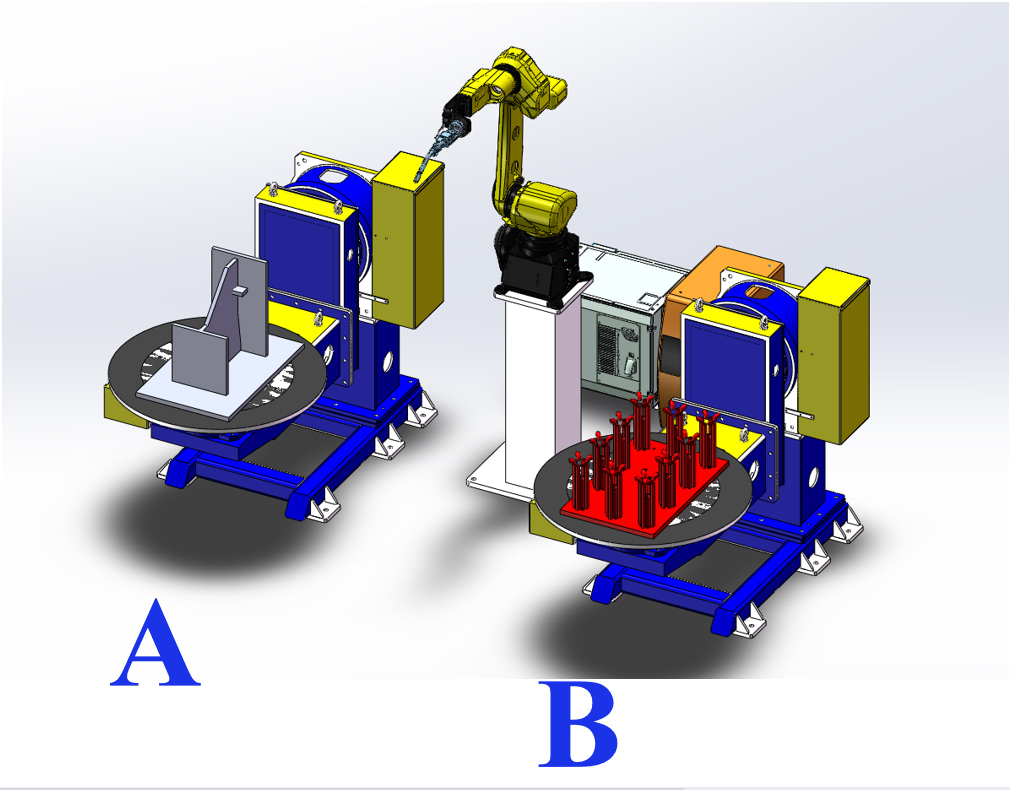

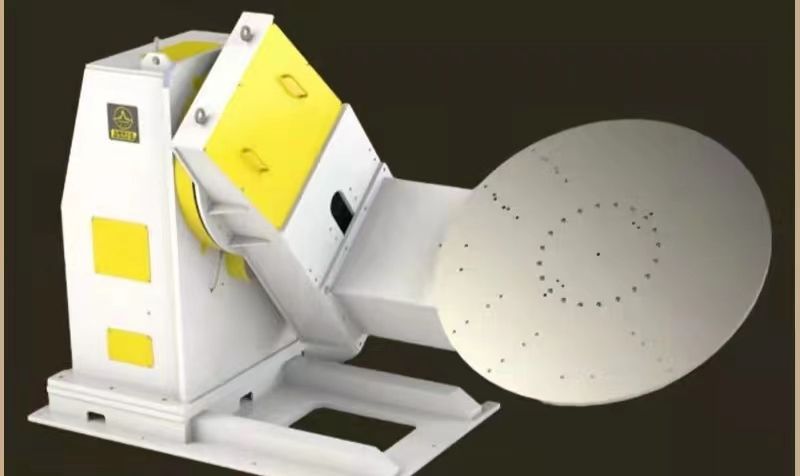

Isikhundla sohlobo lwe-Dual-eksisi L

I-Positioner iyisisetshenziswa esikhethekile sokushisela, esilungele ukufuduka kwe-welding yomsebenzi ojikelezayo, ukuze uthole indawo efanelekile yomshini kanye nesivinini sokushisela. Ingasetshenziswa nge-manipulator kanye nomshini wokushisela ukwakha isikhungo se-welding esizenzakalelayo, futhi ingasetshenziselwa ukukhishwa kwendawo yokusebenza ngesikhathi sokusebenza ngesandla. Okukhiphayo okuguquguqukayo okunokushayela kwe-variable-frequency drive kuyamukelwa ngokuzungezisa ibhentshi lomsebenzi, ngokunemba okuphezulu kokulawula isivinini. Ibhokisi lesilawuli kude lingabona ukusebenza okukude kwebhentshi lokusebenzela, futhi lingaxhunyaniswa ne-manipulator kanye nesistimu yokulawula umshini wokushisela ukuze ibone ukusebenza okuxhunyiwe. Isikhundla sokushisela ngokuvamile sakhiwe umshini wokujikeleza kanye nomshini wokubuyisela webhentshi lomsebenzi. I-workpiece ebekwe ebhentshini lokusebenza ingafinyelela i-welding edingekayo kanye ne-angle yokuhlanganisa ngokuphakamisa, ukujika nokujikeleza kwebhentshi lokusebenzela. Ibhentshi lokusebenzela lizungeza libe ngumthethonqubo wesivinini esiguquguqukayo esingenasinyathelo, esingathola isivinini sokushisela esanelisayo.

Izithombe ezereferensi kuphela, futhi zingaphansi komklamo wokugcina.

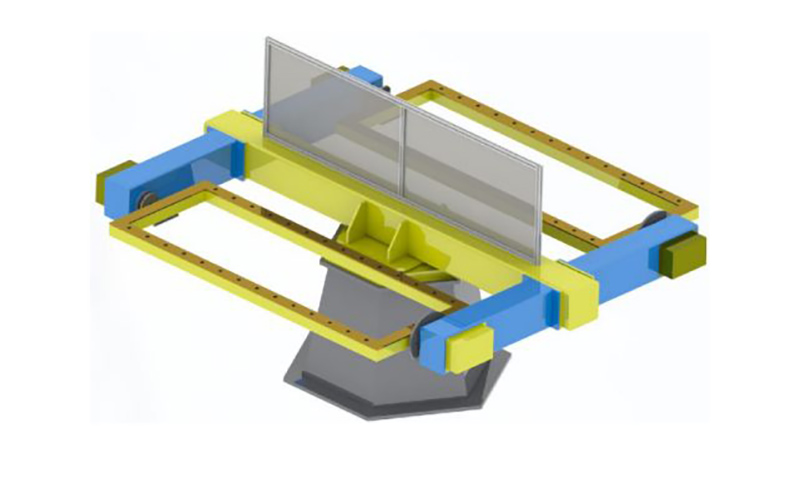

Isibonisi esijikelezayo esinama-eksisi amathathu

1) Isikhundla esijikelezayo esinama-axis amathathu avundlile sakhiwe ikakhulukazi isisekelo esingaguquki esibalulekile, ibhokisi lokuphotha elijikelezayo nebhokisi lomsila, uhlaka lokushisela, i-servo motor kanye nesinciphisi esinembayo, indlela yokuqhuba, ikhava yokuvikela kanye nesistimu yokulawula kagesi, njll.

I-2) Ngokumisa ama-servo motors ahlukene, i-positioner ingasetshenziswa ukude ngomfundisi we-robot noma ibhokisi lokusebenza langaphandle;

3) I-welding edingekayo kanye ne-angle yomhlangano ifinyelelwa ngokuguqula i-workpiece engaguquki ebhentshini lokusebenza;

4) Ukujikeleza kwebhentshi lokusebenzela kulawulwa yi-servo motor, engafinyelela isivinini esihle sokushisela;

5) Izithombe ngezethenjwa kuphela, futhi zingaphansi komklamo wokugcina;

Ukunikezwa kwamandla okushisela

Ilungele ukuhlanganisa, i-lapping, i-joint ekhoneni, i-tube plate butt joint, uxhumano lwe-intersection line kanye namanye amafomu ahlangene, futhi ingakwazi ukubona yonke indawo yokushisela.

Ukuphepha nokuthembeka

Umshini wokushisela kanye nesiphakeli socingo kufakwe ukuvikelwa kwamanje kakhulu, ugesi omningi kanye nokuvikela izinga lokushisa elingaphezu kwamandla. Baphumelele i-EMC kanye nokuhlolwa kokusebenza kukagesi okudingwa yi-GB/T 15579 ejwayelekile kazwelonke, futhi baphumelele isitifiketi se-3C ukuze baqinisekise ukwethembeka nokuphepha okusebenzayo.

Ukongiwa kwamandla kanye nokuvikelwa kwemvelo

Isikhathi sokuthola igesi, isikhathi sokuphakelwa kwegesi kusengaphambili kanye nesikhathi sokuphakelwa kwegesi esalibele kuyalungiseka ukuze kuqinisekiswe ukusetshenziswa okufanele kwegesi. Lapho umshini wokushisela ukhanyisa, uma ungangeni esimweni sokushisela kungakapheli imizuzu emi-2 (isikhathi esilungisekayo), uzongena ngokuzenzakalelayo esimweni sokulala. Vala ifeni futhi wehlise ukusetshenziswa kwamandla.

Isithombe ngesethenjwa kuphela, futhi singaphansi kokukhethwa kokugcina.

Ukunikezwa kwamandla okushisela

Ukuhlanza izibhamu kanye nedivaysi yokufafaza uwoyela we-silicone kanye nedivaysi yokusika ucingo

I-1) Ithuluzi lokufafaza uwoyela we-Silicone esiteshini sokuhlanza isibhamu lisebenzisa i-nozzle ephindwe kabili yokufafaza, ukuze uwoyela we-silicone ufinyelele indawo yangaphakathi ye-torch torch nozzle kangcono futhi uqiniseke ukuthi i-slag yokushisela ngeke ibambelele ku-nozzle.

I-2) Imishini yokuhlanza isibhamu kanye ne-silicone yokufafaza uwoyela iklanyelwe endaweni efanayo, futhi i-robot ingaqedela inqubo yokufafaza uwoyela we-silicone nokuhlanza isibhamu ngesenzo esisodwa kuphela.

I-3) Mayelana nokulawula, ukuhlanza isibhamu kanye nedivaysi yokufafaza uwoyela we-silicone idinga kuphela isignali yokuqala, futhi ingaqalwa ngokuvumelana nokulandelana kwesenzo esicacisiwe.

I-4) Idivaysi yokusika ucingo ithatha isakhiwo sokuzikhandla sesibhamu sokushisela, esiqeda isidingo sokusebenzisa ama-valve e-solenoid ukuyilawula futhi yenza kube lula ukuhleleka kukagesi.

I-5) Idivaysi yokusika ucingo ingafakwa ngokwehlukana noma ifakwe kumshini wokuhlanza isibhamu kanye nedivaysi yokufafaza uwoyela we-silicone ukwakha idivayisi ehlanganisiwe, engagcini nje ngokugcina indawo yokufaka, kodwa futhi yenza ukuhlelwa nokulawulwa kwendlela yegesi kube lula kakhulu.

6) Isithombe ngesethenjwa kuphela, futhi singaphansi kokukhethwa kokugcina.

Uthango lokuvikeleka

1. Setha uthango oluyisivikelo, iminyango yokuphepha noma amagridi okuphepha, izingidi zokuphepha nezinye izinto, futhi wenze ukuvikela okukhiyekayo okudingekayo.

2. Umnyango wokuphepha uzobekwa endaweni efanele yocingo oluvikelayo. Yonke iminyango kufanele ifakwe amaswishi nezinkinobho zokuphepha, inkinobho yokusetha kabusha kanye nenkinobho yokumisa isimo esiphuthumayo.

3. Umnyango wezokuphepha uhlanganiswe nesistimu ngokukhiya ukuphepha (switch). Uma umnyango wezokuphepha uvulwe ngendlela engavamile, isistimu imisa ukusebenza bese ikhipha i-alamu.

4. Izinyathelo zokuvikela ukuphepha ziqinisekisa ukuphepha kwabasebenzi nezinto zokusebenza ngehadiwe nesofthiwe.

5. Ucingo lokuphepha lungahlinzekwa yi-Party A ngokwayo. Kunconywa ukusebenzisa igridi yekhwalithi ephezulu bese ubhaka upende ophuzi oyisixwayiso ngaphezulu.

Uhlelo Lokulawula Ugesi

1. Kufaka phakathi ukulawulwa kwesistimu nokuxhumana kwesignali phakathi kwezinto zokusebenza, okuhlanganisa izinzwa, izintambo, izikhala, amaswishi, njll.;

2. Iyunithi ezenzakalelayo iklanywe ngokukhanya kwe-alamu okunemibala emithathu. Ngesikhathi sokusebenza okuvamile, ukukhanya kwemibala emithathu kubonisa okuluhlaza; uma iyunithi ihluleka, ukukhanya kwemibala emithathu kuzobonisa i-alamu ebomvu ngesikhathi;

3. Kunezinkinobho zokumisa izimo eziphuthumayo ekhabetheni lokulawula irobhothi kanye nebhokisi lokufundisa. Esimeni esiphuthumayo, inkinobho yokumisa izimo eziphuthumayo ingacindezelwa ukuze ubone ukuma okuphuthumayo kohlelo futhi uthumele isignali ye-alamu ngesikhathi esifanayo;

4. Izinhlobonhlobo zezinhlelo zokufaka izicelo zingahlanganiswa ngedivayisi yokufundisa, izicelo eziningi zingahlanganiswa, ezingahlangabezana nezidingo zokuthuthukiswa komkhiqizo kanye nemikhiqizo emisha;

5. Zonke izimpawu zokumisa izimo eziphuthumayo zalo lonke uhlelo lokulawula kanye nezimpawu zokuvala ukuphepha phakathi kwemishini yokucubungula namarobhothi zixhunywe ohlelweni lokuphepha futhi zixhunywe ngohlelo lokulawula;

6. Uhlelo lokulawula lubona ukuxhumana kwesignali phakathi kwemishini yokusebenza njengerobhothi, umgqomo wokulayisha, amathuluzi wokubamba kanye namathuluzi omshini.

7. Uhlelo lwamathuluzi omshini ludinga ukubona ukushintshana kwesignali ngohlelo lwamarobhothi.

Indawo yokusebenza (ihlinzekwe yiqembu A)

| Ukunikezwa kwamandla kagesi | Ukunikezwa kwamandla: izigaba ezintathu ezinezintambo ezine-AC380V±10%, ububanzi bokushintshashintsha kwamandla kagesi ± 10%, imvamisa: 50Hz; Ukunikezwa kwamandla kwekhabhinethi yokulawula irobhothi kuyadingeka ukuthi kufakwe ukushintshwa komoya ozimele; Ikhabhinethi yokulawula amarobhothi kufanele isekelwe ngokumelana nokuphansi ngaphansi kuka-10Ω; Ibanga elisebenzayo phakathi kokunikezwa kwamandla nekhabethe lokulawula ugesi irobhothi lingaphakathi kwamamitha angu-5. |

| Umthombo womoya | Umoya ocindezelweyo uzohlungwa ukuze kukhishwe umswakama nokungcola, futhi ingcindezi yokuphuma ngemva kokudlula ku-triplet izoba ngu-0.5~0.8Mpa; Ibanga elisebenzayo phakathi komthombo womoya kanye nomzimba werobhothi lingaphakathi kwamamitha angu-5. |

| Isisekelo | Isitezi esivamile sikasimende seshabhu ye-Party A izosetshenziselwa ukwelashwa, futhi izisekelo zokufakwa zempahla ngayinye zizomiswa phansi namabhawodi anwetshiwe; Amandla okhonkolo: 210 kg / cm 2; Ubukhulu bekhonkrithi: ngaphezu kuka-150 mm; Ukungalingani kwesisekelo: ngaphansi kuka-±3mm. |

| Izimo Zemvelo | Ukushisa kwe-ambient: 0~45°C; Umswakama ohlobene: 20% ~ 75%RH (akukho condensation); Ukusheshisa kokudlidliza: ngaphansi kuka-0.5G |

| Okunye | Gwema amagesi okuvutha nokugqwala noketshezi, futhi ungachaphazi ngamafutha, amanzi, uthuli, njll.; Gcina kude nemithombo yomsindo kagesi. |