Uhlolojikelele lwephrojekthi

Imidwebo ye-Workpiece: Ingaphansi kwemidwebo ye-CAD ehlinzekwa yi-Party A Izidingo zobuchwepheshe: Ilayisha ubuningi besitoreji sesisele ≥umthamo wokukhiqiza ngehora elilodwa

| Uhlobo Lokusebenza | Ukucaciswa | Isikhathi somshini | Inani lesitoreji/ihora | Inombolo yezintambo | Imfuneko |

| Ipuleti lokucindezela le-SL-344 | 1T/2T/3T | 15 | 240 | 1 | Iyahambisana |

| 5T/8T | 20 | 180 | 1 | Iyahambisana | |

| I-SL-74 Ibhande Lendandatho Ekabili | 7/8-8 | 24 | 150 | 2 | / |

| 10-8 | 25 | 144 | 2 | / | |

| 13-8 | 40 | 90 | 2 | / | |

| 16-8 | 66 | 55 | 1 | / | |

| 20-8 | 86 | 42 | 2 | / |

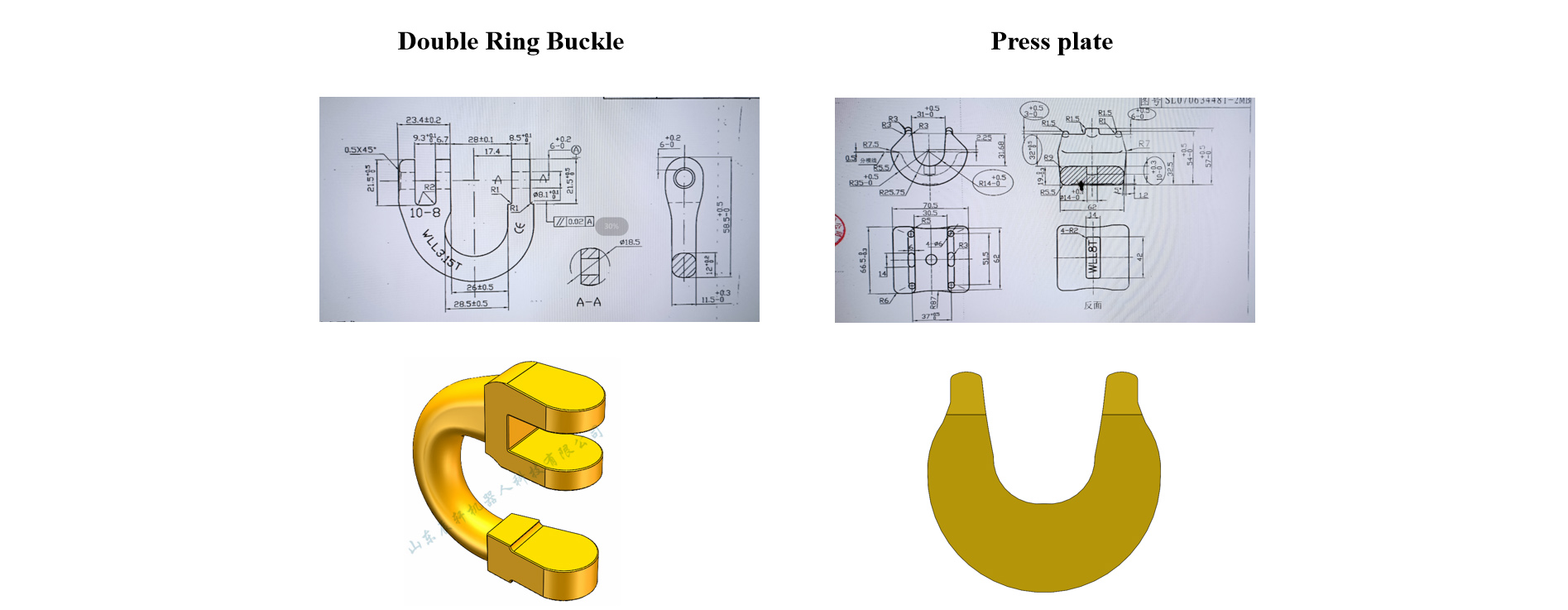

Umdwebo wengcezu yokusebenza, imodeli ye-3D

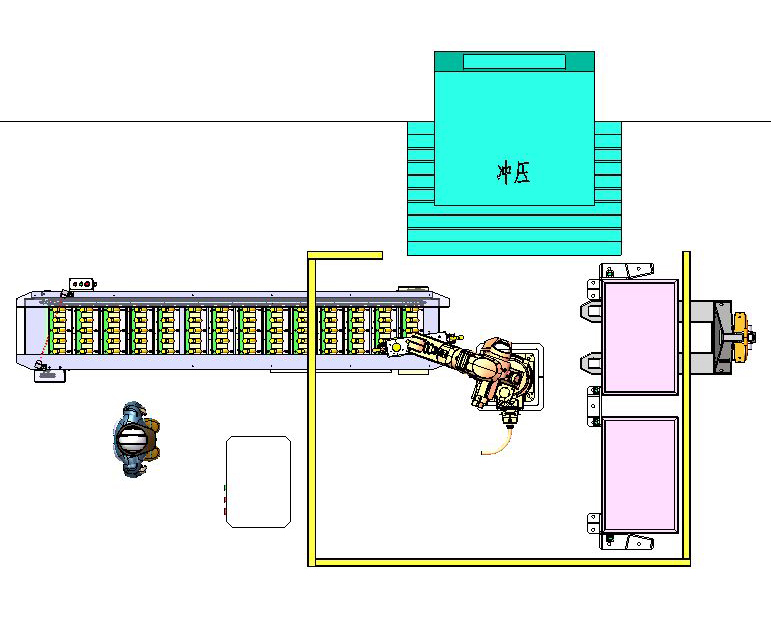

Isakhiwo Sesu

Incazelo: Ubukhulu obunemininingwane bokuhlala bomhlaba buyoba ngaphansi komklamo.

Uhlu Lwezisetshenziswa

Ubhasikidi wokugcinwa kwesikhashana kwamapuleti okuhlukanisa

| I-S/N | Igama | Imodeli No. | Ubuningi. | Ukuphawula |

| 1 | Amarobhothi | XB25 | 1 | I-Chenxuan (kuhlanganise nomzimba, ikhabhinethi yokulawula kanye nombonisi) |

| 2 | I-robot tong | Ukwenza ngokwezifiso | 1 | Chenxuan |

| 3 | Isisekelo serobhothi | Ukwenza ngokwezifiso | 1 | Chenxuan |

| 4 | Uhlelo Lokulawula Ugesi | Ukwenza ngokwezifiso | 1 | Chenxuan |

| 5 | Ilayisha isihambisi | Ukwenza ngokwezifiso | 1 | Chenxuan |

| 6 | Ucingo lokuphepha | Ukwenza ngokwezifiso | 1 | Chenxuan |

| 7 | Idivayisi yokuthola indawo yokuma kozimele | Ukwenza ngokwezifiso | 2 | Chenxuan |

| 8 | Uhlaka olungenalutho | / | 2 | Ilungiselelwe iphathi A |

Incazelo: Ithebula libonisa uhlu lokucushwa lwendawo yokusebenzela ngayinye.

Incazelo yobuchwepheshe

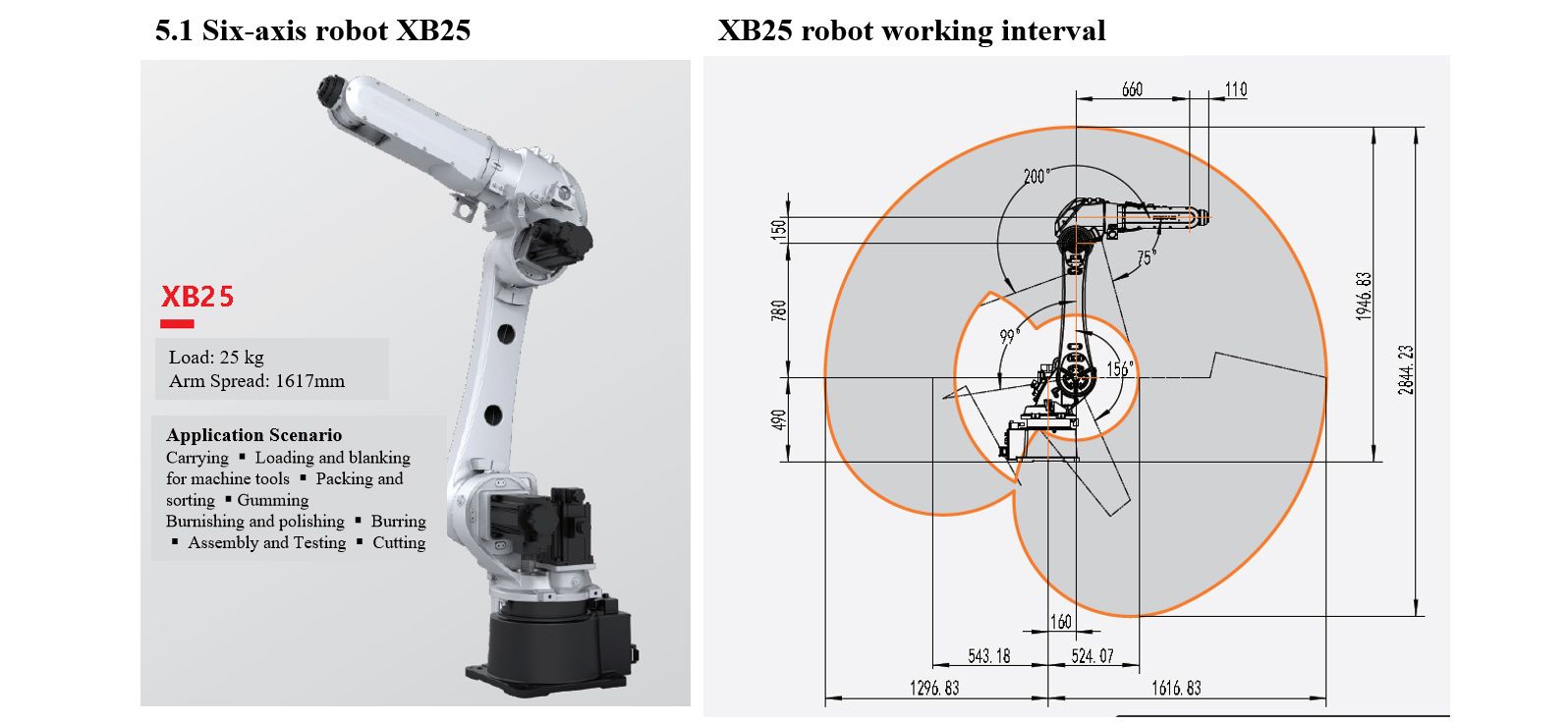

Irobhothi le-axis eyisithupha XB25

Roboter XB25 als grundlegende ipharamitha

| Imodeli No. | Iziqu Zenkululeko | Umthwalo Wesandla | Irediyasi ephezulu yokusebenza | ||||||||

| XB25 | 6 | 25kg | 1617 mm | ||||||||

| Ukunemba kokuma okuphindaphindiwe | Isisindo somzimba | Ibanga lokuvikela | Imodi yokufaka | ||||||||

| ± 0.05mm | Cishe. 252kg | IP65(Wrist IP67) | Iphansi, imisiwe | ||||||||

| Umthombo womoya ohlanganisiwe | Umthombo Wesiginali Ohlanganisiwe | Amandla alinganiselwe e-transformer | Isilawuli esifanisiwe | ||||||||

| 2-φ8 ipayipi lomoya (Amabha angu-8, i-solenoid valve ongakhetha ngayo) | Isignali yamashaneli angama-24 ( 30V, 0.5A ) | 9.5kVA | XBC3E | ||||||||

| Ibanga lokunyakaza | Isivinini esiphezulu | ||||||||||

| I-Shaft 1 | I-Shaft 2 | I-Shaft 3 | I-Shaft 4 | Shaft 5 | Shaft 6 | I-Shaft 1 | I-Shaft 2 | I-Shaft 3 | I-Shaft 4 | Shaft 5 | Shaft 6 |

| +180°/-180° | +156°/-99° | +75°/-200° | +180°/-180° | +135°/-135° | +360°/-360° | 204°/S | 186°/S | 183°/S | 492°/S | 450°/S | 705°/S |

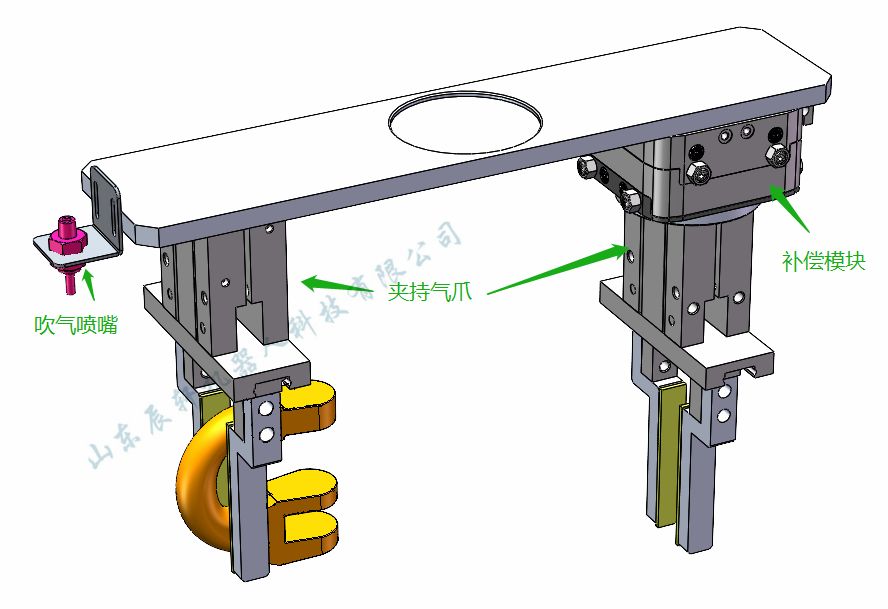

I-robot tong

1. Idizayini yeziteshi ezimbili, ukulayisha okuhlanganisiwe nokuvala isikhala, ekwazi ukubona ukusebenza kokulayisha kabusha okusheshayo;

2. Kusebenza kuphela kuma-workpieces okubamba okucacisiwe, futhi i-tong ihambisana kuphela nokubanjwa kwezinto zokusebenza ezifanayo phakathi kwebanga elithile;

3. Ukubamba ugesi kuqinisekisa ukuthi umkhiqizo ngeke uwe ngesikhathi esifushane, okuphephile futhi okuthembekile;

4. Iqembu lemibhobho ye-pneumatic enesivinini esiphezulu lingahlangabezana nomsebenzi wokuvunguza komoya esikhungweni somshini;

5. Izinto ezithambile ze-polyurethane zizosetshenziselwa ukugoqa iminwe ukuze kugwenywe ukuncinzwa kocwecwe;

6. Imoduli yesinxephezelo inganxephezela ngokuzenzakalelayo ukuma kwe-workpiece noma amaphutha we-fixture kanye nokuhluka kokubekezelelana kwe-workpiece.

7. Umdwebo ungowokubhekisela kuphela, futhi imininingwane izoba ngaphansi komklamo wangempela.

| Idatha Yezobuchwepheshe* | |

| I-oda No. | XYR1063 |

| Ukuxhuma ama-flange ngokuya nge-EN ISO 9409-1 | tk 63 |

| Umthwalo onconyiwe [kg]** | 7 |

| X/Y uhambo lwe-eksisi +/- (mm) | 3 |

| Centre Retention Force (N] | 300 |

| Non-center Retention Force [N] | 100 |

| Umfutho womoya omkhulu osebenzayo [ibha] | 8 |

| Izinga lokushisa eliphansi lokusebenza [°C] | 5 |

| Izinga lokushisa eliphezulu lokusebenza [°C] | +80 |

| Ivolumu yomoya esetshenziswa umjikelezo ngamunye [cm3] | 6.5 |

| Isikhathi se-inertia [kg/cm2] | 38.8 |

| Isisindo [kg] | 2 |

| *Yonke idatha ikalwa ngomfutho womoya ongu-6 bar **Uma kuhlangene esikhungweni |

Imojuli yesinxephezelo

Imojula yesinxephezelo inganxephezela ngokuzenzakalelayo ukuma kwengcezu yokusebenza noma amaphutha wesakhiwo kanye nokuhluka kokubekezelelana kwe-workpiece.

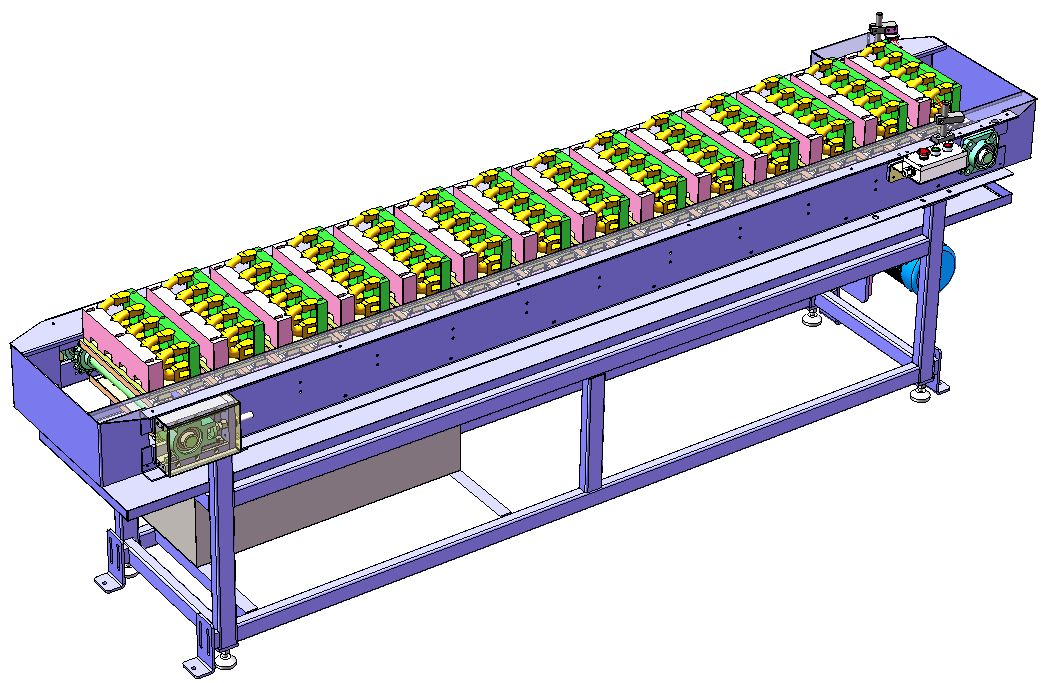

Umugqa wokulayisha nokudlulisa

1. Ulayini wokulayisha nokudlulisa wamukela uhlaka oludlulisa ungqimba olulodwa lweketango, olunomthamo omkhulu wokugcina, ukusebenza ngezandla okulula nokusebenza kwezindleko eziphezulu;

2. Inani eliklanyelwe lemikhiqizo ebekiwe lizohlangabezana namandla okukhiqiza ehora elilodwa. Ngaphansi kwesimo sokuphakelwa okujwayelekile kwezandla njalo emizuzwini engama-60, ukusebenza ngaphandle kokuvala shaqa kungenziwa;

3. Ithreyi lezinto ezibonakalayo alinaphutha, ukuze lisize ukuthulula okwenziwa ngesandla ngesandla, kanye namathuluzi esililo ezingxenyeni zokusebenza ezinemininingwane ehlukene kuzolungiswa mathupha;

4. Izinto ezimelana nowoyela namanzi, ezilwa nokungqubuzana namandla aphezulu zikhethwa ithreyi lokuphakela le-silo, futhi ukulungiswa ngesandla kuyadingeka lapho kukhiqizwa imikhiqizo ehlukene;

5. Umdwebo ungowokubhekisela kuphela, futhi imininingwane izoba ngaphansi komklamo wangempela.

Uhlelo Lokulawula Ugesi

1. Kubandakanya ukulawulwa kwesistimu nokuxhumana kwamasignali phakathi kwezinto zokusebenza, okuhlanganisa izinzwa, izintambo, i-trunking, amaswishi, njll.;

2. Iyunithi ye-automatic yakhelwe ngesibani se-alamu esinemibala emithathu. Ngesikhathi sokusebenza okuvamile, isibani esinemibala emithathu sibonisa okuluhlaza; futhi uma iyunithi yehluleka, isibani esinemibala emithathu sizobonisa i-alamu ebomvu ngesikhathi;

3. Kukhona izinkinobho zokumisa izimo eziphuthumayo ekhabetheni lokulawula kanye nebhokisi lokubonisa irobhothi. Esimeni esiphuthumayo, inkinobho yokumisa izimo eziphuthumayo ingacindezelwa ukubona isitobhi esiphuthumayo sohlelo futhi ithumele isignali ye-alamu ngesikhathi esifanayo;

4. Ngombukiso, singakwazi ukuhlanganisa izinhlobo eziningi zezinhlelo zesicelo, ezingahlangabezana nezidingo zokuvuselela umkhiqizo kanye nokwengeza imikhiqizo emisha;

5. Zonke izimpawu zokumisa izimo eziphuthumayo zalo lonke uhlelo lokulawula kanye nezimpawu zokuvala ukuphepha phakathi kwemishini yokucubungula ukweba kanye namarobhothi axhunywe ohlelweni lokuphepha futhi ukulawulwa okuhlanganisiwe kwenziwa ngohlelo lokulawula;

6. Uhlelo lokulawula lubona ukuxhumana kwesignali phakathi kwemishini yokusebenza njengamarobhothi, izisele zokulayisha, izindlawu kanye namathuluzi omshini wokwenza imishini;

7. Uhlelo lwamathuluzi omshini ludinga ukubona ukushintshana kwesignali ngohlelo lwamarobhothi.

Ithuluzi Lomshini Wokucubungula (kuhlinzekwe ngumsebenzisi)

1. Ithuluzi lomshini wokwenza imishini kufanele lifakwe indlela yokukhipha i-chip ezenzakalelayo (noma ukuhlanza izinsimbi zensimbi ngesandla nangokujwayelekile) kanye nomsebenzi wokuvula nokuvala umnyango ozenzakalelayo (uma kukhona umshini wokuvula nokuvala umsebenzi);

2. Ngesikhathi sokusebenza kwethuluzi lomshini, ama-iron chips awavunyelwe ukugoqa ama-workpieces, okungase kuthinte ukuqiniswa nokubekwa kwamarobhothi ama-workpieces;

3. Uma kucatshangelwa ukuthi kungenzeka yini ukuthi imfucumfucu ye-chip iwele ekubunjweni kwethuluzi lomshini, i-Party B yengeza umsebenzi wokufutha komoya odlalweni lwamarobhothi.

4. Iqembu A lizokhetha amathuluzi afanelekile noma ubuchwepheshe bokukhiqiza ukuze kuqinisekiswe ukuphila kwamathuluzi okunengqondo noma ukushintsha amathuluzi ngokushintsha ithuluzi ngaphakathi kwethuluzi lomshini, ukuze kugwenywe ukuthikameza ikhwalithi yeyunithi ezishintshayo ngenxa yokuguga kwamathuluzi.

5. Ukuxhumana kwesignali phakathi kwethuluzi lomshini nerobhothi kuzosetshenziswa Iqembu B, futhi Iqembu A lizohlinzeka ngamasignali afanelekile wethuluzi lomshini njengoba kudingeka.

6. Irobhothi libeka ngendlela embi lapho likhetha izingxenye, futhi ithuluzi lomshini libona ukuma okunembile ngokwephoyinti lereferensi yocezu lokusebenza.

Ucingo lokuphepha

1. Setha ucingo oluyisivikelo, umnyango wokuphepha, ilokhi yokuphepha nezinye izinto, futhi wenze ukuvikela okuxhumene okudingekayo.

2. Umnyango wokuphepha uzobekwa endaweni efanele yocingo lokuphepha. Yonke iminyango izofaniswa neswishi nenkinobho yokuphepha, inkinobho yokusetha kabusha kanye nenkinobho yokumisa izimo eziphuthumayo.

3. Umnyango wezokuphepha uhlanganiswe nesistimu ngokukhiya ukuphepha (switch). Uma umnyango wezokuphepha uvulwe ngendlela engavamile, isistimu iyama futhi inikeze i-alamu.

4. Izinyathelo zokuvikela ukuphepha ziqinisekisa ukuphepha kwabasebenzi nezinto zokusebenza ngehadiwe nesofthiwe.

5. Ucingo lokuphepha lungahlinzekwa yi-Party A uqobo. Kunconywa ukushisela ngegridi yekhwalithi ephezulu bese upenda ngevarnish yesitofu esiyisixwayiso esiphuzi ngaphezulu.

Ucingo lokuphepha

Ukhiye wokuphepha

Ucingo lokuphepha Indawo yokusebenza (ihlinzekwe yiqembu A)

| Ukunikezwa kwamandla kagesi | Ukunikezwa kwamandla: Izigaba ezintathu zezintambo ezine AC380V±10%, uhla lokuguquguquka kwamandla kagesi ±10%, imvamisa: 50HZ;Ukunikezwa kwamandla kwekhabhinethi yokulawula irobhothi kufanele kufakwe inkinobho yomoya ezimele; Ikhabhinethi yokulawula amarobhothi kufanele isekelwe ngokumelana nokuphansi ngaphansi kuka-10Ω;Ibanga elisebenzayo phakathi komthombo wamandla nekhabhinethi yokulawula ugesi irobhothi kufanele libe phakathi kwamamitha angu-5. |

| Umthombo womoya | Umoya ocindezelweyo uzohlungwa uphume emanzini, igesi nokungcola, futhi ingcindezi yokuphuma ngemva kokudlula ku-FRL izoba ngu-0.5~0.8Mpa; Ibanga elisebenzayo phakathi komthombo womoya nomzimba werobhothi lizoba phakathi kwamamitha angu-5. |

| Isisekelo | Phatha ngephansi elivamile likasimende endaweni yokusebenzela ye-Party A, futhi isisekelo sokufakwa kwempahla ngayinye sizomiswa phansi ngamabhawodi anwetshiwe; Amandla kakhonkolo: 210 kg/cm2;Ukuqina kukakhonkolo: Ngaphezu kuka-150 mm;Ukungalingani kwesisekelo: Ngaphansi kuka-±3mm. |

| Izimo Zemvelo | Izinga lokushisa le-ambient: 0~45 ℃;Umswakama ohlobene: 20%~75%RH (akukho ukufingqa okuvunyelwe); Ukusheshisa kokudlidliza: Ngaphansi kuka-0.5G. |

| Okunhlobonhlobo | Gwema amagesi okuvutha nokugqwala noketshezi, futhi ungachaphazi ngamafutha, amanzi, uthuli, njll.; Ungasondeli emthonjeni womsindo kagesi. |